A team of mechanical engineering researchers were able to advance their research in the field of atomization and sprays by utilizing the resources available at the U.S. Department of Energy’s Argonne National Laboratory.

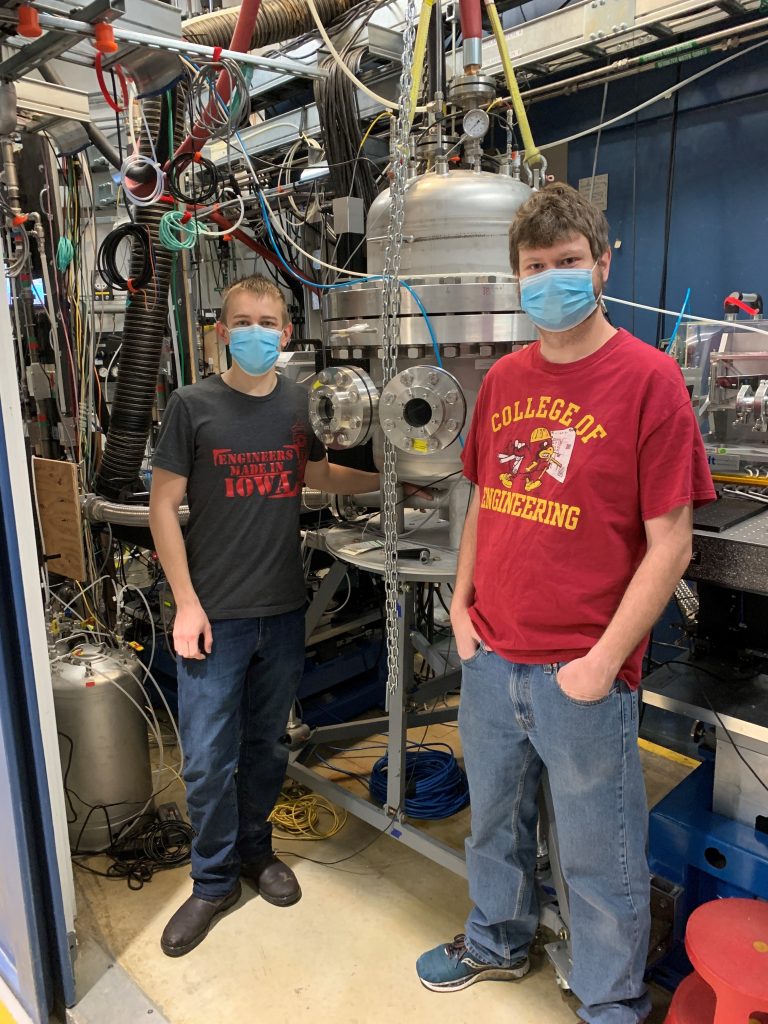

Ted Heindel, Bergles Professor of Thermal Science and university professor in mechanical engineering (ME), led a group from his Experimental Multiphase Flow Lab which also included Tim Morgan, postdoctoral research associate, and Tim Dahlstrom, M.S. student in ME. The researchers spent 13 days at the 1700-acre Argonne facility located southwest of Chicago.

“We utilized Argonne’s synchrotron X-ray source, the Advanced Photon Source or APS, to collect imaging data of high-pressure atomized sprays using the high-intensity X-rays APS produces,” said Dahlstrom. The APS is a DOE Office of Science user facility.

“Our setup was almost entirely remote-controlled,” Dahlstrom said, “so after five grueling days of setting up all of our equipment, plumbing, and wiring in a very small hutch, most of the remaining time was spent at a computer setting the conditions and recording nearly nine terabytes of images.”

The engineers were able to advance their research, using the lab’s unique resources which are not available on campus at Iowa State.

“The unique capabilities of the Advanced Photon Source allow us to measure the spray characteristics with a temporal and spatial accuracy that would not be possible by any other means,” said Morgan, adding they were able to observe the movement of water inside the aluminum nozzle body at 10 micron spatial resolution and 20 microsecond temporal resolution.

The team utilized fluid mechanics, measurement and instrumentation, controls, and design in developing their system and conducting their research. Much of their research examined how spray formation is affected by various gas/liquid momentum ratios as well as ratios of swirling air to straight-flowing air. The recent trip to Argonne gave them the opportunity to focus more on how changes in the ambient pressure affect the mechanisms by which the spray is produced.

In advance of their trip to Argonne, Heindel’s team designed and manufactured a Chamber for Assorted Pressurized Spray sUrveiLlancE, or CAPSULE that they could transport and use at different locations. Tom Burtnett, who holds his M.S. and B.S. in ME from Iowa State, played a crucial role in the design of the CAPSULE, part of which served as his master’s project. The team utilized their knowledge of electronics and instrumentation to develop the CAPSULE, which has real-time remote control of seven flow parameters and remote monitoring of 30 additional parameters to provide the researchers with data about pressure, temperature and flow throughout the system.

“Because of Tom’s work, we were able to relatively quickly and easily install the experiment in the fairly small experiment hutch at APS, acquire our data, and then remove the experiment to make room for the next user,” said Morgan, who holds a Ph.D. in ME and HCI, a M.B.A., and a B.S. in ME all from Iowa State.

For Dahlstrom, it was an opportunity to develop skills and knowledge beyond just what he learns in the classroom.

“I learned a lot about electronics just by the need to build some of these circuits, such as building cable assemblies and soldering circuit boards,” said Dahlstrom. “The experience of working in a national lab was very rewarding, stressful, exciting and exhausting.”

Given the high demand of the Argonne facilities, the Cyclone engineers had just six days to gather their data. Despite the pressure Dahlstrom felt that “everything had to go right” coupled with the long hours and the COVID-19 protocols (such as being limited to just three on-site researchers instead of the usual six), the researchers considered the trip to be a success. In particular, they were happy with how many conditions they were able to test despite the challenges and time limitations. Adding the dimension of ambient pressure into the mix multiplied the number of test conditions by five, but they still managed to get the data they were after.

The team also credits physicist Alan Kastengren, who holds his B.S. in ME from Iowa State (and a Ph.D from the University of Illinois Urbana-Champaign), as their main contact at Argonne. This recent visit marks the fifth time that Heindel’s team has visited Argonne to conduct research. Heindel, who also serves as the director of Iowa State’s Center for Multiphase Flow Research and Education, said that he appreciates the opportunity to bring his students to Argonne so they can experience a laboratory and research setting outside of campus.

“Whenever we visit, it always makes me feel like a graduate student again because we spend long hours in the lab and focus all of our energies on getting the data we are after,” he said.