In Roman mythology, the god Janus had two faces so that he could see clearly into both the past and future.

Janus particles have a similar dual nature, because they are engineered to have two surfaces, each with distinct physical properties. One combination for a Janus particle is to have one side hydrophilic (attracted to water) and the other hydrophobic (water repellant).

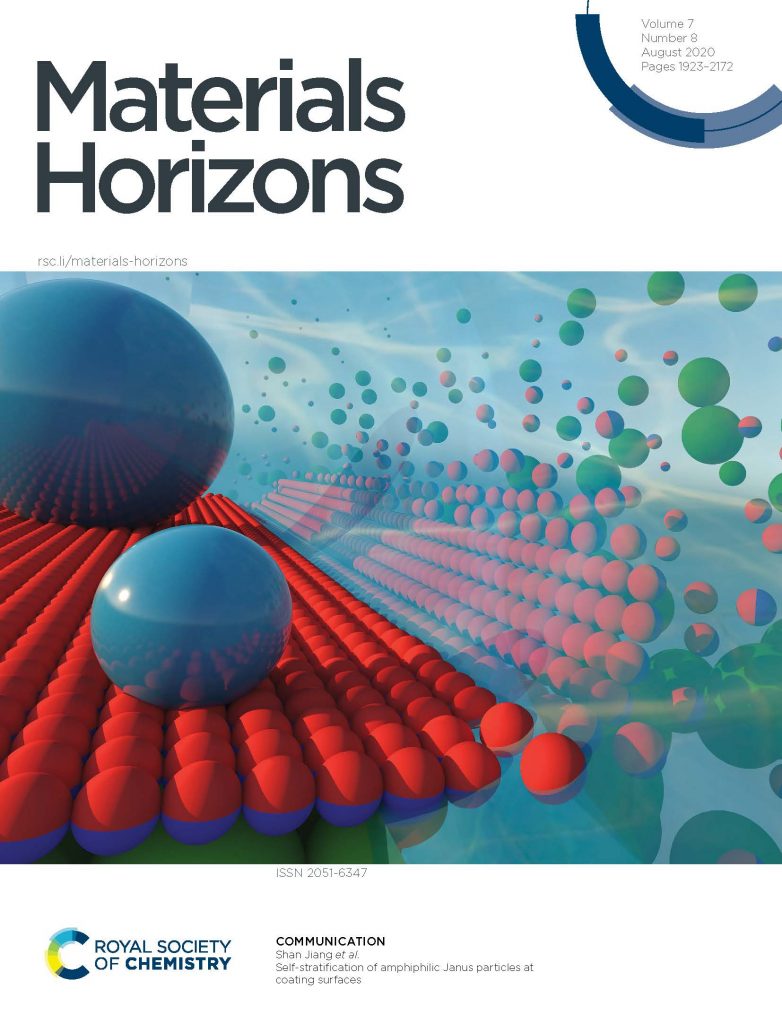

Until recently, Janus particles could not be produced in large quantities, and their commercial applications were unclear. New research led by Shan Jiang, assistant professor of materials science and engineering, shows that the nanoparticles could be the key to more environmentally friendly paints and coatings. The results were published in the August issue of Materials Horizons.

“Previous studies are heavily focused on structures formed by these particles at a very small scale, because they have unique surface properties,” Jiang said. “In this study, we are trying to use these particles to improve the performance of paints and coating, which no one has ever thought about.”

Jiang collaborated with Chunhui Xiang, an Iowa State assistant professor of apparel, events and hospitality management and Xin Yong, an assistant professor in the Department of Mechanical Engineering at the Thomas J. Watson College of Engineering and Applied Science at the University of Binghamton.

Multifaceted, multifunctional

Think for a minute about painting a wall in your house or apartment. To do it properly, there are a few general methods. You can do a primer layer and then a paint layer, which can take twice the time. You can mix paints with solvents, but solvents are a health risk and fumes can be an issue in poorly ventilated spaces. Or you can use water-based paints such as latex or acrylic latex, but many of those still contain solvents and may not be as durable.

Manufacturers of electronics, furniture and numerous other products face the same options for the products they make, and they must choose what makes sense for each individual item being made.

For the paper “Self-stratification of amphiphilic particles at coating surfaces,” the team mixed hydrophilic/hydrophobic Janus particles with commercial paints, then painted surfaces to see how the particles would react.

The result: The hydrophilic side oriented to the surface and helped the coatings adhere better, while the hydrophobic side faced toward the surface and made it water-repellant. The researchers also found that the particles diffused and arranged themselves into self-stratifying layers more quickly and in ways that did not completely follow their hypotheses.

“Currently no theory can be used to explain the self-stratification behaviors of Janus particles,” Jiang said. “However, more studies are warranted to probe the detailed mechanism [of the particles]. I hope by fully understanding the principles in Janus particle self-stratification, we will be able to design next-generation ‘smart’ coating materials that are more environmentally friendly with better properties.”

Layered future uses

The research team believes that Janus particles can prove to be beneficial in many other applications, including cosmetics, 3D printing and drug formulations.

“The future research in this area will go in parallel in two directions,” Yong said. “Professor Jiang and I need to understand what’s really going on here, so we plan to do more systematic study on that. On the other hand, there’s a lot of interest to utilize this self-layering idea to make better or more functional coatings.

“The long-term vision is to be able to develop a coating that has multiple components that will self-layer when it dries. Each layer would give you the desired property.”

Other contributors to the research include Iowa State postdoctoral researcher Fei Liu; Iowa State graduate students Yifan Li, Ayuna Tsyrenova, Kyle Miller, Emily Olson and Rebecca Mort; Iowa State undergraduate researcher Devin Palm; and Binghamton University graduate student Shensheng Chen.