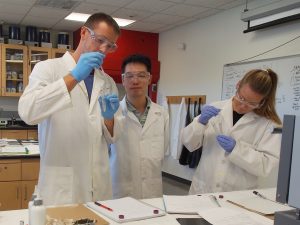

Shan Jiang, a new assistant professor in materials science and engineering, is pioneering new technology in nano-engineering and biomaterials.

Shan Jiang, a new assistant professor in materials science and engineering, is pioneering new technology in nano-engineering and biomaterials.

Jiang received his Ph.D. from the University of Illinois and held a post-doc at the Massachusetts Institute of Technology (MIT). After he finished his post-doc, Jiang went into the industry for one of the largest chemical companies in the world, DOW Chemical Company.

His position with DOW Chemical Company was the project leader within the business R&D sector, and he worked with a strong research and development department that dealt with coating materials such as paint and other architectural coatings. In this role, Jiang did not just do research, he also constantly interacted with clients and other departments.

“I had to wear many different hats, which ultimately helped me develop invaluable and necessary communication and presentation skills,” says Jiang.

After three years of working in industry, Jiang still felt a strong passion for teaching and missed his days doing fundamental research in academia. That’s a big part of why he was so excited to join Iowa State as an assistant professor this fall.

“Iowa State provides great research facility, faculty, and students, so I knew I made a good choice,” explains Jiang.

Now that he has settled in with the materials science and engineering department, Jiang is continuing his research on the Janus particle, named after the Roman god Janus who has two faces looking into the opposite directions. Like Janus, the particle with the same name is made up of two different chemistries on opposite sides. For example, the composition can consist of one side being hydrophobic while the other side being hydrophilic, just like a surfactant molecule.

Janus particle can self-assemble when the two different chemistries attract their kin, eventually forming clusters with unique shape and geometry. And these particles can be really small, almost 1000 times smaller than a human hair. The self-assembly procedure is like the T-1000 robot in Terminator 2 comes to life, intricate structures can be generated with these simple small particles by coming together all by themselves. Janus particles can also adsorb at oil and water interface to help stabilize emulsions. This new system offers a novel way to fabricate advanced functional materials which may find applications in many different areas.

Janus particle can self-assemble when the two different chemistries attract their kin, eventually forming clusters with unique shape and geometry. And these particles can be really small, almost 1000 times smaller than a human hair. The self-assembly procedure is like the T-1000 robot in Terminator 2 comes to life, intricate structures can be generated with these simple small particles by coming together all by themselves. Janus particles can also adsorb at oil and water interface to help stabilize emulsions. This new system offers a novel way to fabricate advanced functional materials which may find applications in many different areas.

Jiang hopes to take advantage of his blended background in both academia and industry, and apply Janus particles to practical applications, such as drug delivery, coating material, and agro-science. Janus particle can be fabricated into a new environmentally responsive smart delivery system, help co-deliver drugs, genes and imaging agents. Janus particle can also be formulated to make better coatings, not only for wall and devices, but also for seeds, to protect and provide nutrients.

While doing his research, Jiang is also teaching physical and mechanical properties of polymers (MAT E 453), a class on both theory and experimentation of polymers. For the first time, Jiang introduces the industrial coating test methods to Iowa State classroom, and uses commercial paints as examples to help students establish the concepts of real product and train them with skills necessary for their future career. The students also got chance to design his or her own paint at the end of the semester.

“My main goal is not just to teach students textbook knowledge, but also to be able to prepare students for their future career by helping them get trained on skills are needed for job hunting and career development,” says Jiang.

Jiang plans to establish a lab that focuses on soft matter and biomaterials. He plans to find a way to scale up Janus particle synthesis and one day manufacture the new particles commercially.