Two Iowa State researchers teamed up with researchers from UCLA and Princeton University to create an innovative way to engineer the flow of fluid streams, which is important in biological processing, controlling chemical reactions and creating structured materials.

Baskar Ganapathysubramanian, assistant professor of mechanical engineering, and Yu Xie, research graduate assistant in mechanical engineering, recently published an article called “Engineering Fluid Flow Using Sequenced Microstructures” in the journal Nature Communications.

The article detailed the importance of directing the shape of co-flowing fluid streams, a process that Ganapathysubramanian says can be applied across disciplines in a range of situations, from the very small to the macro-scale.

“There are literally infinite possibilities and applications of this discovery,” Ganapathysubramanian added.

Before their research, limited strategies existed for manipulating the form and motion of fluid streams.

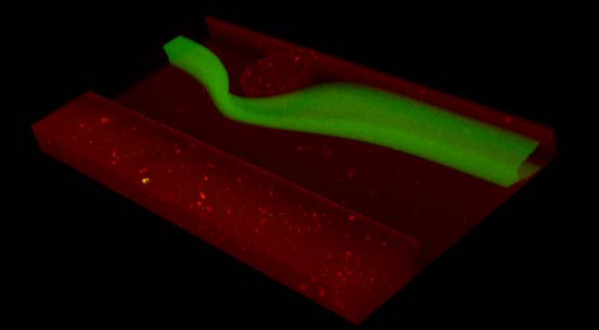

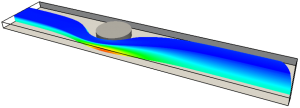

With this project, the team investigated a different method that included developing “a hierarchical approach to engineer fluid streams into a broad class of complex configurations.” The researchers used sequences of fluid transformations to create order and control, unlike previous approaches that created chaotic flows.

The central operators for the flow scheme were cylinders positioned in various cross-stream locations to produce significant flow deformations. Using multiple pillars downstream of one another magnified the disrupted flow effect.

“This sequential placement of different types of pillars offers enormous flexibility to tailor the fluid stream for various critical applications,” said Ganapathysubramanian. “Controlling the shape and location of co-flowing fluid streams provides a fundamental tool for creating structured materials, preparing biological samples and engineering heat and mass transport.”

Other uses include tailoring tissue growth, cooling large data-center warehouses efficiently, fabricating interlocking fibers to improve the properties of composite materials and maximizing light exposure to algae for the production of biofuels.

The team has been researching and experimenting for two years, during which time the biggest challenge has been exploring the space of configurations, which are the specific values of four different elements: size of the pillar, location of the pillar, size of the channel and speed of the fluid.

Xie developed smart and effective automated tools that enabled the group to explore the large set of configurations and gain insight from the data.

Ganapathysubramanian noted that the group made use of high-performance computing clusters to solve their configurations—especially Cystorm, the ISU supercomputer and the NSF XSEDE supercomputers.

Co-authors of the article include Hamed Amini, Elodie Sollier, Mahdokht Masaeli and Dino Di Carlo from the Department of Bioengineering at UCLA, and Howard A. Stone from the Department of Mechanical and Aerospace Engineering at Princeton University.