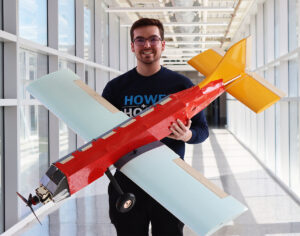

Just as their aircraft did, pride soared in the Make To Innovate program’s Design Build Fly student team in a dynamic return to an important national competition after an absence of many years.

The Design Build Fly event, sponsored by the American Institute of Aeronautics and Astronautics, allows undergraduate and graduate student teams the opportunity to design and build a remote-controlled aircraft to perform specific tasks. From a total of 107 teams entered this year, the ISU group finished 46th. View the full scoring rundown.

“We are extremely proud. To do so well with this particular group of students’ first attempt was amazing,” said team lead Justin Pope.

The 12-student team was composed entirely of undergraduates. In the spring semester it was led by senior Pope with assistance of graduate student Ahmad Siddique. The team completely planned, designed, built and tested their craft during the 2023-24 academic year.

The 12-student team was composed entirely of undergraduates. In the spring semester it was led by senior Pope with assistance of graduate student Ahmad Siddique. The team completely planned, designed, built and tested their craft during the 2023-24 academic year.

The competition includes both a “ground mission” component with the aircraft configured to accomplish specific tasks, and a flight performance where the craft must be flown by remote control through specific maneuvers. A written report must also be submitted in advance.

“It involved hundreds of man hours,” says Pope. “We didn’t have structured class time for this. We had a required one hour per week for grading purposes for the course. But all the work was done outside of class. We held our own meetings with the various teams involved with the plane – system integration, operations, mechanical. The senior members of the team sometimes put in 20 hours a week.”

A total of three planes were actually constructed and tested over a period of months. Development was not without its challenges. “The first plane flew in December, but the landing gear broke off. We put that plane aside and built a second version,” says Pope.

Many test flights were performed with the second plane, but just three days prior to heading to the competition a gust of wind caught the plane as it was landing and it crashed nose-first into the ground. Though the electronic components of the plane survived, special laser-cut structural parts were damaged beyond repair. Fortunately, duplicate parts had been created in the M:2:I lab and were immediately pressed into service. “We constructed a new plane in just two days, transferred the electronics from the crashed plane and headed into the event with a new competition plane,” Pope explains.

Spur-of-the-moment structural configuration changes needed to be made on-site at the competition to meet the initial inspection. Frequently changing wind conditions from one day to the next proved challenging for the flight competition.

“I have to praise team member Jonathan Hien,” says Pope. “He was the project manager for the first semester. He put his blood sweat and tears into this project and is a big part in our massive success this year. He has also put a lot of work into the process for next year’s team.”