Soft composites consisting of liquid metal (LM) droplets have shown outstanding promise to create new materials for soft and stretchable electronics and robotics. However, techniques to control droplet shape and orientation are lacking, which ultimately limits the properties of the materials.

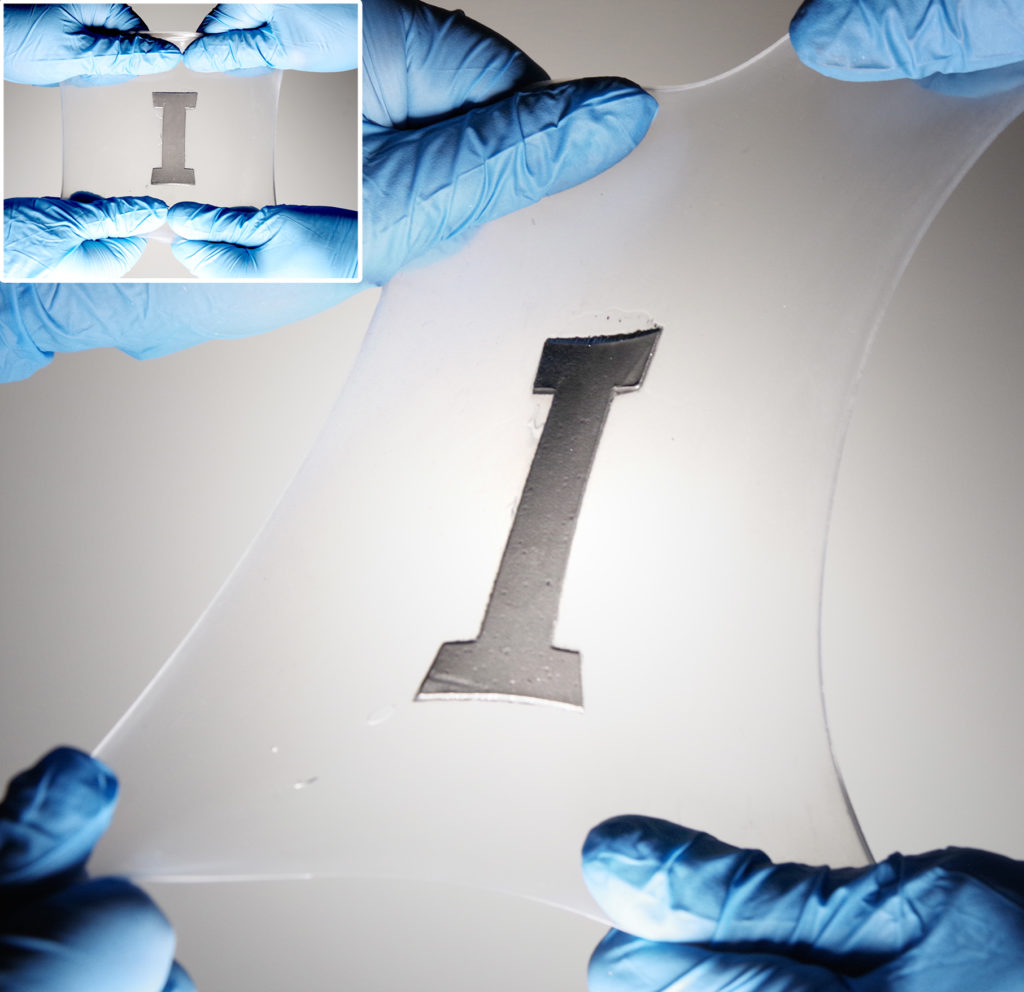

A team led by Iowa State University’s Michael Bartlett has created a new composite, called a liquid metal programmed elastomer (LMPE), where liquid metal can be loaded up to 70% in precise, programmable patterns throughout the material.

LMPE shows a promising combination of properties needed for tomorrow’s wearable electronics and soft robotics: metal-like thermal conductivity and elastomer-like stretchability.

The team’s work appears in the April 29 issue of Advanced Functional Materials.

Soft yet thermally conductive

Most soft materials trap heat, but many emerging soft technologies require high thermal conductivity.

Engineers have seen liquid-metal droplet composites as a promising candidate for many emerging applications, but existing materials processing methods offered only limited ability to control droplet structure. To gain precise control over properties, precise control over metal droplet shape and arrangement was needed.

Enter LMPE. These composites have high liquid metal volume loadings while controlling the shape and orientation of droplets – both necessary to achieve exceptional thermal conductivity. What’s more, the liquid nature of the inclusions does not degrade the overall mechanical properties of the composite.

“We were able to mechanically shape and then thermally relax the composites to program liquid-metal droplets and arrange the droplets into microstructures” said Bartlett, assistant professor of materials science and engineering. “We can do this throughout a rubber material, creating soft materials in stress-free conditions with some of the highest thermal conductivity we have seen. We can further tune directionality, opening up anisotropic properties.”

Programmable structures, exceptional properties

The precise microstructural programming and high liquid-metal loading offers high conductivity and rapid heat dissipation, all in a flexible, stretchable material.

“We can change droplet aspect ratio as much as five times. When combined with high liquid metal loadings, our materials show a 70-times increase in thermal conductivity over the base polymer, while actually being softer,” said A B M Tahidul Haque, first author on the paper and postdoctoral research associate.

The researchers anticipate these properties being using for many different fields.

“The ability to program LM microstructure in LMPEs enables a combination of high thermal conductivity and soft mechanical response which can support thermal management in technologies such as stretchable devices and integrated electronics, wearable prosthetics, robotics, and 3D printed structures.” said Bartlett.

Other co-authors on the paper include Ravi Tutika, graduate student in materials science and engineering, and Rachael L. Byrum, a sophomore in mechanical engineering.

Bartlett’s work is supported with a Defense Advanced Research Projects Agency Young Faculty Award.