A challenge issued by SpaceX and Tesla Motors CEO, Elon Musk, is reaching its final stages. In an attempt to make a more efficient transportation system, Musk issued an open challenge for teams to create a “Hyperloop pod” that can travel 700 mph, making the trip from San Francisco to Los Angeles only 20 minutes long. Teams that made it past the first round of preliminary design will meet at Texas A&M University on January 29 and 30 where their final models will be judged.

Two of these teams will represent Iowa State: ISU Hyperloop (read more about ISU Hyperloop and the competition here), and AEOLUS. The smaller of the two teams, AEOLUS, consists of five students from different disciplines. “With our small team, it’s been easy to share information, negotiate, and make everyone’s ideas part of the final design,” said mechanical engineering senior Yilong Liu.

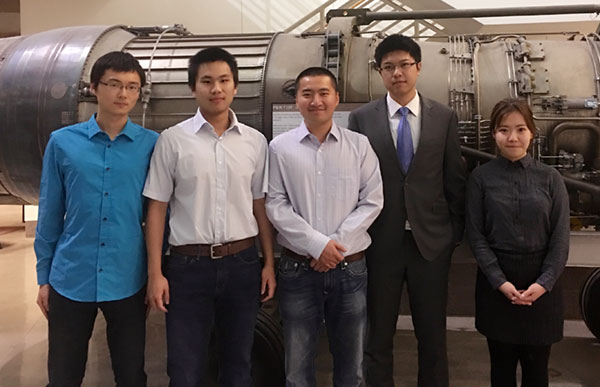

The team, comprised of Liu, ME senior Haoxiang Qin, MatE seniors Chengguang Zhao and Yuxuan Xiao, and landscape architecture junior Yanni Yang, chose their name after the ruler of winds in Greek mythology. Their group is one of approximately 300 heading to this weekend’s competition, down from the 1,000 international and domestic teams that entered the competition where 700 teams were eliminated in the first round.

The funding for their work comes from their advisor, Ming-Chen Hsu. Hsu and one of his graduate students, Fei Xu, have helped AEOLUS along the way, providing advice to the team and answering questions they have.

AEOLUS’s team members have been meeting four to five nights a week since they formed their group in August. After lots of designing and testing of numerous models, the team has decided on a model with a carbon fiber shell and an aluminum alloy for the compressor, heating center, combustion turbine and controllable propulsion system.

“We used the common alloy A356 because it’s light, tough, cheap and has a high capacity to absorb energy,” said Zhao. Their pod runs on batteries, so it creates no emissions and operates while levitating above the tract. Yang, who did the exterior and interior design work, said she wanted people to be able to “feel the fast” in the design.

The team is confident they will do well in the competition because of extensive testing and capable team members. “It really just feels natural that we made it to the next round,” said Zhao. “I know this is a great team, and because of all the successful things we’ve done, I’m sure we can make it through this second step.”