Jonathan Claussen applies carbon nanotube technology to a new propulsion system

Collaborating with researchers at Brigham Young University and the U.S. Naval Research Laboratory, Jonathan Claussen is taking a well-known propulsion technique to the nanoscale.

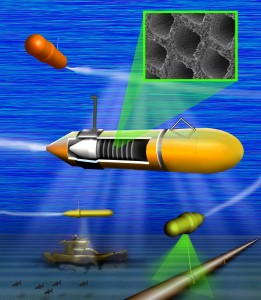

The team has developed a system that uses hydrogen peroxide decomposition to propel small underwater vehicles.

“Hydrogen peroxide propulsion has been in use from as early as WWII. It’s a great resource because it has a minimal impact on the environment and it’s inexpensive,” explained Claussen, assistant professor of mechanical engineering.

The small underwater vehicles he is working on are designed to perform simple missions, such as deliver a payload or place a sensor, in confined spaces. They are also environmentally friendly and can disintegrate once a task is completed.

Claussen’s research group has been focused on developing a catalyst that could decompose the hydrogen peroxide into oxygen. The team partnered with Brian Iverson, assistant professor at BYU, who was developing multiwalled carbon nanotube microarray membranes. Claussen says he knew Iverson’s technology would be a great platform for the project.

“We functionalized the arrays Dr. Iverson was developing with platinum nanoparticles,” Claussen said. “This approach created a platinum-carbon nanotube matrix with microscale pores, providing a catalyst that allows the hydrogen peroxide to seep through the pores to react and efficiently form gas.”

He adds that using this approach resulted in more efficient activation energy than conventional catalysts and other nanostructured catalysts that use platinum.

Finding the ideal carbon nanotube catalyst took patience as the team is working with something that’s 100,000 times smaller than a human hair. “After you make it, you can’t see it, so we have to use a scanning electron microscope to visualize what we’ve done. Sometimes you have to go back to the drawing board, other times it’s something very small to change the density of the nanoparticles on the nanotube arrays,” Claussen said.

The propulsion system may have broader applications beyond the project for the U.S. Naval Research Laboratory, including being scaled up to use on larger underwater vehicles. Claussen says propeller-based underwater vehicles can’t make tight turns or supply quick bursts of energy (propulsion), which are both important for docking a vehicle into a recharging station.

Before he came to Iowa State, Claussen worked at the U.S. Naval Research Laboratory and saw how powerful collaboration can be. “By working with our two partners, we were able to complete this project in about a year,” he said. “I hope to continue these sorts of collaborations to take applied nanotechnology to the next level. We’ve spent the time working on fundamental research, and it’s exciting to be ready to move nanotechnology into the governmental and private industries to develop it further.”

Claussens’ project recently appeared in ACS Nano entitled “High Aspect Ratio Carbon Nanotube Membranes Decorated with Pt Nanoparticle Urchins for Micro Underwater Vehicle Propulsion via H2O2 Decomposition.” He discussed the technology in an ACS Nano podcast, available at: http://pubs.acs.org/page/ancac3/audio/index.html.