A laser in Iowa State University’s Wind Energy Manufacturing Laboratory scanned layer after layer of the flexible fiberglass fabric used to make wind turbine blades.

A computer took the laser readings and calculated how dozens of the layers would fit and flow over the curves of a mold used to manufacture a blade. And if there was a wrinkle or wave in the fabric — any defect at all — the technology was designed to find it.

That’s because the last thing you want is a defect in a 40-meter wind turbine blade when it’s spinning in the wind.

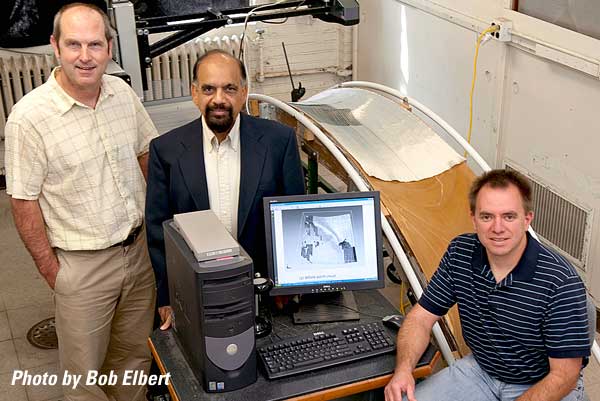

“Waves in the fabric are bad because they can’t take the load,” said Vinay Dayal, an Iowa State associate professor of aerospace engineering.

“And if a blade can’t take the load, bad things happen to the turbine,” said John Jackman, an Iowa State associate professor of industrial and manufacturing systems engineering.

The two are working with Frank Peters and Matt Frank, associate professors of industrial and manufacturing systems engineering, to operate and develop Iowa State’s Wind Energy Manufacturing Lab.

The lab has been open for about a year and was built as part of a three-year, $6.3 million research project. The study is a joint effort of researchers from TPI Composites, a Scottsdale, Ariz.-based company that operates a turbine blade factory in Newton, and the U.S. Department of Energy’s Sandia National Laboratories in Albuquerque, N.M. The researchers’ goal is to develop new, low-cost manufacturing systems that could improve the productivity of turbine blade factories by as much as 35 percent.