Silence is golden, as the saying goes. Its significant value in scientific research can be found in the anechoic chamber in the Department of Aerospace Engineering. “Anechoic” means free from echo, and an anechoic chamber is a room designed to replicate an infinite field where no echoes bounce back.

Dr. Anupam Sharma, an associate professor of aerospace engineering, has worked with the anechoic chamber at Iowa State University since he joined the department in 2012. The chamber is located in Howe Hall, the home of the Department of Aerospace Engineering, and Sharma estimates it to be around 30-40 years old.

Turning down the noise

There are essentially two functions with an anechoic chamber: eliminating echoes from inside the chamber and sounds from the outside. First, says Sharma, “You have to somehow take the sound that is being emanated, produced inside of the chamber, and absorb it so that there are no reflections.” This is achieved by placing foam, or, in the Iowa State chamber and other older chambers, glass fiber blocks all around the walls, ceiling and floor of the room. These blocks are wedge-shaped structures that absorb and dampen the acoustic waves produced by whatever is being tested in the chamber. Completely dampening sound to zero is impossible in a finite space, says Sharma, but the chamber can lessen it to almost zero.

The other main function of an anechoic chamber is blocking out extraneous noise. Concrete can be used on the outside of the chamber to block out noise, but if the chamber needs to be more movable, often thick metal is used.

The frequency capabilities of the Iowa State anechoic chamber range from about 200 hertz up to about 20 kilohertz. “If you think of an acoustic wave, it has a certain wavelength, so one wave will occupy a certain space and, depending on its frequency, it’ll be larger or smaller,” says Sharma. Lower frequencies have larger wavelengths and higher have smaller. The waves produced go into the foam wedges and get slightly dampened every time they hit the wall, so by the time they come back, they have been reduced to nearly nothing.

Many projects and experiments have been conducted in the chamber. Two of the most prominent were the owl wing research project led by Sharma, and an ongoing project, a Department of Energy (DOE) assignment creating ultrasonic whistles to deter bats from approaching wind turbine blades. Information from the United States Geological Survey (USGS) states that an estimated hundreds of thousands of bats are found dead from wind turbines each year.

According to the article, “Engineer looks to owl wings for bio-inspired ideas for quieter aircraft, wind turbines,” published by Iowa State News Service in 2017, the owl wing research was supported by the National Science Foundation and the Iowa Space Grant Consortium, along with Argonne Leadership Computing Facility supporting computer research time.

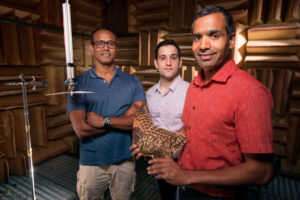

Sharma and his fellow researchers studied the silent flight of the owl and tested it on different devices. The associate professor and his team used some of the owl’s characteristics and applied them to propellers, which they then tested in the anechoic chamber. This research could potentially lead to vehicles with much quieter or silent flight.

Going to bat for bats with ultrasonic whistles

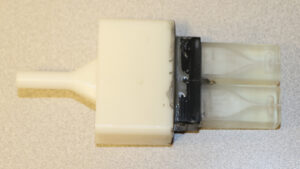

The DOE project is based on producing whistles that create noise in the ultrasound, similar to the idea of a dog whistle. “The idea here is to produce a lot of ultrasound, and this ultrasound field then creates so much noise that bats cannot hear the echo. At least that’s the theory,” says Sharma. Bats’ echolocation is in the ultrasound frequency, and they use it to find food in the dark. Sharma and his team have created whistles that can take airflow and produce ultrasound-jamming noise to hopefully deter bats from wind turbines.

Zhangming Zeng is a department graduate student who has studied under Sharma and has just earned a Ph.D. He has been the primary researcher in the anechoic chamber for the DOE ultrasonic whistles. His research project is titled “Novel Ultrasonic Bat Deterrents Based on Aerodynamic Whistles” and studies how to use the whistles to help stop bats from colliding with wind turbine blades. He started working with the chamber in 2019, making modifications to get it to how it looks now. With delays in shipping due to COVID the changes were not complete until early 2021.

Zeng came to Iowa State to pursue his Ph.D. after receiving his master’s degree from the University of Florida and his bachelor’s degree at Beijing University of Aeronautics and Astronautics. His school friends spoke highly of the ISU aerospace engineering program, and after communicating with the faculty, he knew Iowa State was the place for him. “I feel like ISU is quite supportive to the graduate students, so that’s a reason, as well as international students here, so all in all, that’s the reason I chose Iowa State,” says Zeng.

The owl wing research has come to a close, but the DOE research on bats and the ultrasonic whistles is ongoing, and Sharma says they have used the anechoic chamber significantly for the design of the instrument.

“The way I think of the anechoic chamber is that it is really supplementing what we can do with computer modeling,” he says. He prefers physical experiments for the ultrasonic whistle instead of computer modeling because it is more impressive to demonstrate how it works. The whistles are 3D models that can be made in less than a day. They are 3D printed primarily in Howe Hall. Because of the testing in the anechoic chamber, the DOE is comfortable enough to use the whistles in a field test. Sharma and his team will be taking their whistles to the University of Minnesota to field test them.

The ultrasonic whistles are placed in the center of the chamber and surrounding them is an arc with microphones placed on it to pick up the sound. From the outside of the chamber, Zeng uses an airflow system that was built and attached to the anechoic chamber specifically for his experiment to send air through the whistle. He then uses Python code to decipher the data.

Zeng says he believes he could not have successfully completed any of his research on the ultrasonic whistles without the department’s anechoic chamber. He agreed with Sharma, saying, “For the numerical method, the good thing is that it gives you an idea of what’s happening inside your device, however, most software, no matter if it’s commercial or owned by an institute or some kind of privately-owned or government-owned software, the issue is that they give you an answer, but you can’t know if it is completely accurate.” The anechoic chamber allows them to test their simulations in real-life experiments and confirm their numerical data.

The chamber is just one example of unique laboratory spaces within the Department of Aerospace Engineering that enhance important developments in the field and offer fulfilling opportunities for students in their quest to pursue their career goals.