Richard L. Handy Professor David White implements a technology that revolutionizes more than 80 years of soil compaction testing.

On a typical road and building construction site, soil is compacted to properly support the structure built above it. Manual quality assurance tests, which are traditionally done with handheld instruments, test soil density, thickness and uniformity in isolated areas. In recent years, state transportation departments have experienced low numbers of personnel to conduct the already scattered tests.

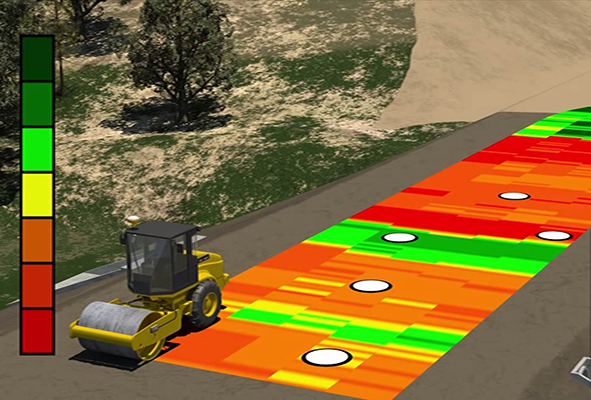

White and his research team identified a technological need to conduct more accurate soil compaction testing. They developed intelligent soil compaction technology. It uses new technology on a compactor, along with global positioning system (GPS) technology, to give the operator a real-time view of roller pass coverage. Three methods of machine-ground interaction aid in measurements: 1) frequency-domain analysis of accelerometer data, 2) force displacement analysis using dynamic models, and 3) monitor machine power through roller drum sinkage. Data are collected on a machine-integrated computer. They also can be transferred to a computer off site for analysis. Visual output portrays a color spectrum of soil stiffness: red means low stiffness; yellow means intermediate stiffness; and green means high stiffness. Soil stiffness correlates to soil strength.

The difference in accuracy between manual testing and roller testing is astronomical. “By instrumenting rollers with integrated measurement technology, we can go from less than a tenth percent (coverage) to nearly 100 percent (coverage),” White said. “Everywhere the roller goes, we get the information.”

Intelligent compaction exposes weak soil areas easier, allowing the roller operator to eliminate weak soil before further site construction. This increases project reliability and decreases life cycle costs.

Under White’s lead, this technological advancement attracted 11 state transportation agencies to form the Technology Transfer for Intelligent Compaction Consortium (TTICC). These states include California, Georgia, Iowa, Kentucky, Mississippi, Missouri, Ohio, Pennsylvania, Utah, Virginia, and Wisconsin. Watch a video on TTICC at www.ceer.iastate.edu/tticc.

“The TTICC program in Ames, Iowa, is a great tool for education,” said Daniel Clark, chief of the Evaluations and Research Unit at Pennsylvania Department of Transportation. “I see it as a train-the-trainer type of development. As I interact with my counterparts in other states, we share experiences and stories of what works and what doesn’t work.”

Caterpillar, JB Holland Construction (Decorah, Iowa), and McAninch (Des Moines, Iowa) are key partners in implementing soil compaction technology on site.