“It’s the MacGyver skills that employers really love.” So says Department of Chemical and Biological Engineering faculty member Nigel Reuel in discussing a new course in the department that helps make the important link between applying hands-on experience and chemical engineering concepts.

Ch E 4290 – Chemical Engineering Product Design is a new offering that associate professor Reuel helped design. Registration for the course in the fall 2024 semester is going on now and eligible students are encouraged to consider getting it onto their schedule. The course is elective, carries three credits and has two prerequisite courses.

It’s an important dose of “science meets business” and offers future chemical engineers a whole new angle of developing marketable skills. The curriculum includes a roster of guest lecturers from industry to share their insights.

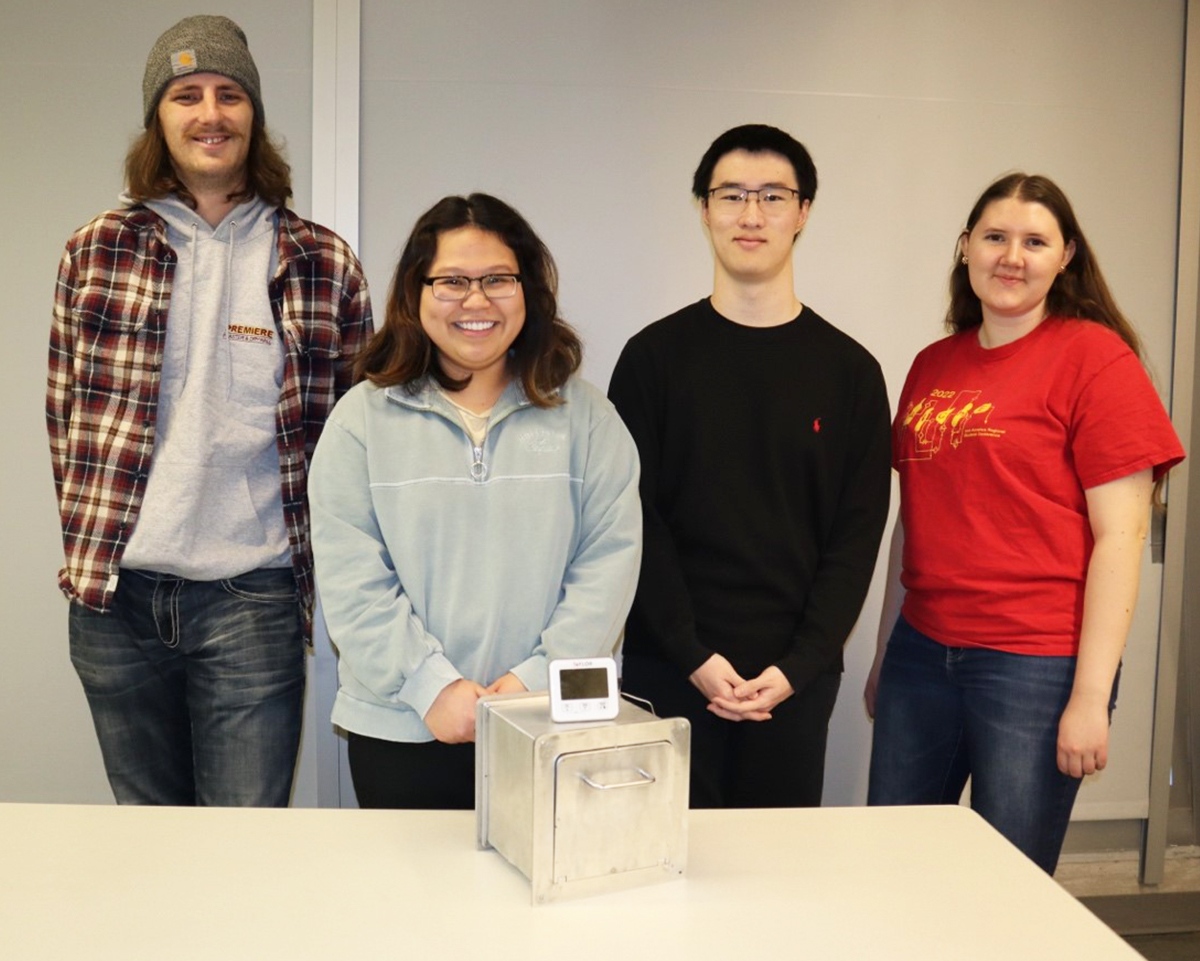

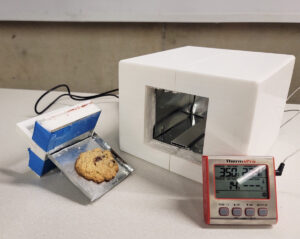

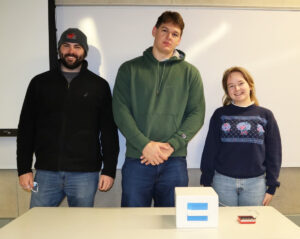

The course begins with students forming a “company team” and receiving a client brief, a document that provides an overview, and key specifications for the semester product. In the fall 2023 course the product to create was a portable oven appropriate for outdoor activity, and accompanying formulated cookie mix. The oven needed to be powered by a 12V solar battery, be light enough to hike with, and yield a fully baked three-inch diameter cookie. The cookie mix needed to be shelf-stable and readied by simply mixing with water. Throughout the semester, assessments centered on project deliverables such as patent search, modeling, and design plans.

Of course, a final product needs some marketing. Teams conducted customer research and created commercials for their products. At the end of the semester, the teams aired their commercials and demonstrated the ovens they constructed live in class. Reuel guides students through the product development process with lessons on consumer research, marketing research, developing pitches, and product promotion.

“No other course in the chemical engineering curriculum is like this,” wrote one student in their course evaluation. “I have not been able to take an idea all the way to a final product that I built myself in any other class.”

“The guest speakers expanded my knowledge of chemical engineering career paths and options that I need to consider,” wrote another student in an evaluation.

The hands-on experience found in the class was unanimously cited as a highlight during the teams’ final demonstrations. Fabricating the prototype ovens required tools like waterjet cutters, 3D printers, soldering irons, video production software, and drill presses. The Student Innovation Center houses many of the tools needed and offers training for students who haven’t used the equipment before.

Summing up the experience, one student shared in the course evaluation: “My understanding of chemical engineering evolved throughout this course to be more holistic. I largely regarded chemical engineering from the process design and chemical formulation side of things, but this course provided me with a more in-depth understanding of a whole new side of the field that involves the consumers and the economic and business aspects of the products being created.”