New ME professor explores engineering design under uncertainty and the design of lithium-ion rechargeable batteries

After he gained a B.E. in engineering physics from Tsinghua University and a Ph.D. in mechanical engineering from the University of Maryland, College Park, Chao Hu spent four years in the medical device industry. Now, he is ready to share his industry experience with students and engage in more research as an assistant professor in mechanical engineering at Iowa State.

After he gained a B.E. in engineering physics from Tsinghua University and a Ph.D. in mechanical engineering from the University of Maryland, College Park, Chao Hu spent four years in the medical device industry. Now, he is ready to share his industry experience with students and engage in more research as an assistant professor in mechanical engineering at Iowa State.

Hu has two main focus areas for his research, the first of which is engineering design under uncertainty. In this research area, the techniques of reliability analysis and design optimization are integrated to develop reliability-based design methodologies that offer probabilistic approaches to engineering design.

“Reliability-based design attempts to find the optimum design of an engineered system that will minimize the cost and satisfy a target reliability, while also accounting for uncertainty in parameters and design variables,” he says.

Hu works with methods that enable efficient uncertainty propagation and reliability analysis. These methods drastically reduce the computational cost of reliability-based design, and have the potential to broaden the application of engineering design under uncertainty to complex engineered systems, such as aircrafts and nuclear power plants. “These are engineered systems that have large dimensions and/or involve expensive simulations.”

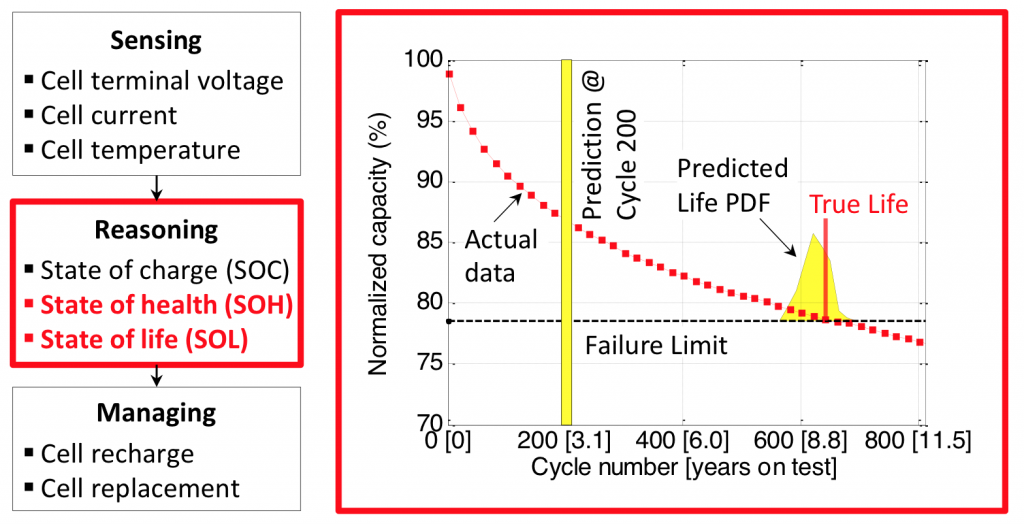

The second focus of his research is on design for failure prevention of lithium-ion batteries. Hu is working to develop robust prognostic methods for improving the operational reliability and safety of the lithium-ion battery. “Compared to conventional batteries, a lithium-ion battery has a higher energy density, which contributes to its success but also raises safety concerns,” Hu says. “For example, a lithium-ion battery pack could rupture or even explode under short-circuit conditions.”

To address these issues, Hu is developing prognostic methods to predict the remaining useful life of a battery while taking into account various sources of uncertainty (e.g., cell-to-cell variations and future loading conditions).

To address these issues, Hu is developing prognostic methods to predict the remaining useful life of a battery while taking into account various sources of uncertainty (e.g., cell-to-cell variations and future loading conditions).

His approach uses fast and efficient machine learning techniques to speed up data processing for on-board applications.

“The success of this research will produce major advancements in extending battery life and durability, and will potentially lead to development of battery-powered vehicles that are more reliable and efficient than current models and that can drive farther on a single charge,” he adds.

While Hu is very passionate about his research, he is thrilled to start teaching. “I love interacting with students and seeing that I can transfer my knowledge to students while also learning from them.”

Before coming to Iowa State, Hu worked as a principal scientist at Medtronic in Minneapolis, Minnesota. Medtronic is the world’s largest medical technology company, specializing in implantable medical devices such as pacemakers, defibrillators and neurostimulators.

These devices need batteries to run, so Hu’s work on lithium-ion rechargeable batteries started at Medtronic. “I worked for a while on reliability analysis, modeling, designing and testing for the next generation of rechargeable batteries. After that, I started to focus on developing and evaluating new battery chemistries to meet emerging needs.”

Both Hu and his wife, Li, will be teaching at Iowa State this fall (Li works in the accounting department in the College of Business). Their jobs have kept them living in different cities since the time they met, so they are excited to finally be together in Ames.

“I would have to travel back and forth between Minnesota and Washington, D.C., all the time. It’s been a long journey, but we are so glad that we are now working at the same place, and we will live together to raise our little one here in Ames.”