It started as a passing fascination with an insect. Andrew Hillier, chair and Wilkinson Professor of Interdisciplinary Engineering of the Department of Chemical and Biological Engineering at Iowa State University, observed a brilliant purple-blue wasp on his driveway at home and wondered at its intense color.

“This insect, called a steel blue cricket hunter, is pretty—with an intense, iridescent purple-blue shell. But that color isn’t due to pigment. It’s due to the structure on the surface of the insect’s body,” Hillier explains.

This phenomenon is not unique to the wasp; many insects and birds display similar coloration with the same science behind it.

In the case of the wasp and other insects like it, it displays what is known as structural color. This color can arise from an exoskeleton that is composed of a periodic surface pattern that interacts with light. When light hits the surface of the exoskeleton certain wavelengths are absorbed and others scatter.

“In some cases, the surface consists of a series of exceedingly thin layers, which create constructive and destructive interference, and the color that you see is the result of that particular combination of nanoscale layers,” explains Hillier.

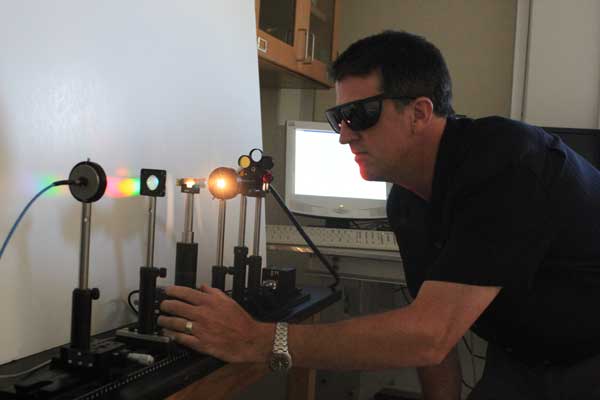

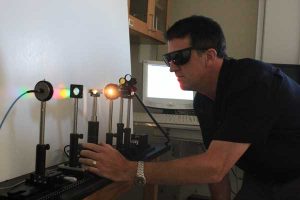

The science of light has intrigued Hillier for years. And it’s why his research group at Iowa State has been working since 2006 to harness the science of that structural color into tools for biosensing, a technology that converts a biological response into a measurable signal, such as a color change, in order to detect the presence of a particular analyte.

Recently awarded a $450,000 grant from the National Science Foundation, Hillier is conducting ongoing research to imitate these nanostructures found in nature. But he’s doing it in a slightly different way.

Hillier is creating nanostructures across a surface rather than down into it, and combining these layers with a metal film. The combination, when exposed to light, excites an oscillation of electrons along the surface called a surface plasmon.

“Depending on how we arrange the surface and how we hit it with light, we can create a structure that produces a very specific color. For example, we can make a surface that appears red and becomes a deeper red when something absorbs onto it. The nanoscale control allows you to define the color, where it is in the visible spectrum and to a degree how intense it is. You can even make multiple colors on a single surface using more complex surface structures. So these devices are beautiful as well as full of information.”

The surface can then be constructed to detect a specific protein, DNA molecule, pathogen or pollutant.

“In some ways, these surfaces function like a traditional piece pH paper, where a simple dip into solution produces a color change, but in this case you can be highly specific and sensitive,” says Hillier. These biosensors have a wide range of potential uses in medicine, public health, environmental monitoring, food safety, defense, and forensics.

His group started the research experimenting with a nanostructured surface that most people have lying around their house—a compact disc.

“These disks are made of polycarbonate plastic, with grooves stamp-melted into them at a spacing of about 1.5 micrometers. It’s what gives them their rainbow-colored appearance and what helps a laser track its position on the disc. Coincidentally, it’s also a really convenient spacing for exciting a surface plasmon,” says Hillier.

Hillier’s research team has also used DVD and Blu-Ray discs to inexpensively experiment with before developing their own manufacturing techniques for creating metal-coated sensor chips with nanostructures that are precisely tuned to create a desired signal.

“It’s a very simple visual cue to see a color change, but in a quantitative sense it’s also a really significant and an easily measurable signal,” says Hillier. “You can use a spectrometer, a CCD camera, a photodetector, or even your own eye. There are all kinds of options that can be small, miniaturized, highly sensitive, portable, and even parallelized, so you could have arrays of different sensors to detect a number of different analytes on the same instrument.”

Hillier’s most recent work looks at taking the sensing capabilities of the chips even further, combining the quantitative information available from surface plasmon resonance sensing methods with a more traditional analytical technologies, such as infrared spectroscopy.

“The problem with infrared is that it will tell you what, but not how much,” said Hillier. “We’re exploring the possibility of combining the two spectroscopies into a new type of instrument where we can measure chemistry with infrared and quantity with the surface plasmon.”

Hillier’s research has also yielded a number of theoretical models that can accurately predict the behavior of these biosensors. The models allow Hillier’s research group to computationally design a biosensor and calculate how light will interact with its structure.