Modern manufacturing is seeing rapid changes in the workplace. One change is integration of artificial intelligence (AI) and automated technologies like Automated Guided Vehicles (AGV) into operational processes.

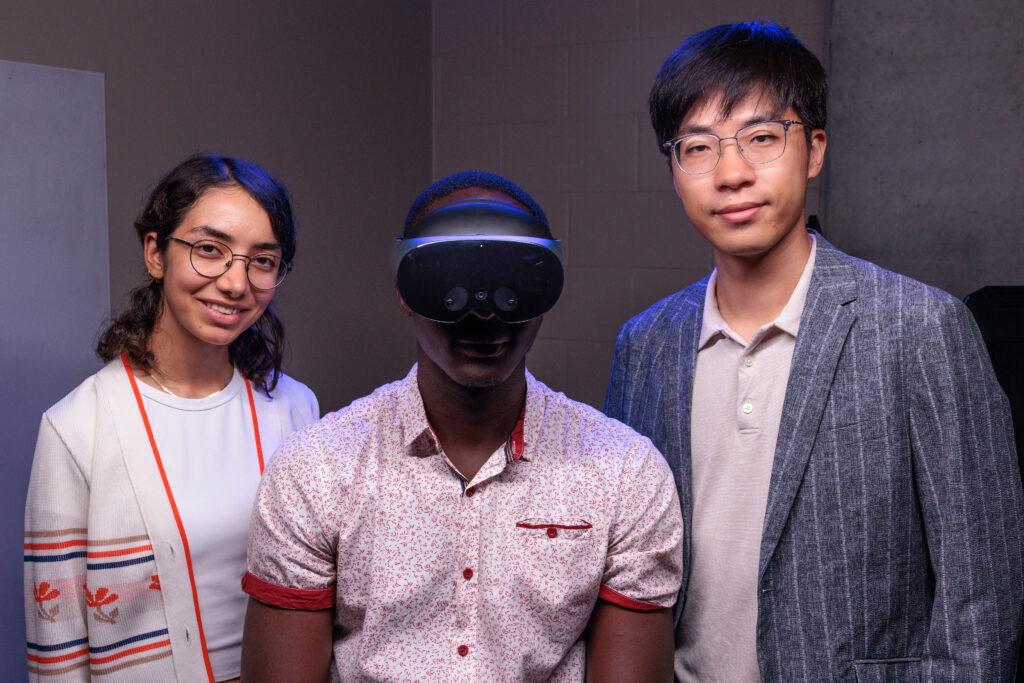

Jundi Liu, assistant professor of industrial and manufacturing systems engineering, graduate student Mobina Amrollahi, and undergraduate research assistant Rindirisia Wangira are actively conducting AGV/human trust laboratory studies using a virtual reality apparatus for human-robot interaction research.

Trust plays a crucial role in human-autonomy interaction, acting as a cognitive mediator influencing human behavior during these interactions.

Use of AGVs offers increased flexibility, better space utilization, improved factory floor safety, reduced overall operating cost and more accessible interface with other automated systems for manufacturers. Variability in human trust, however, plays a part in optimizing AGV effectiveness.

For workers in the manufacturing environment who are more cautious, gaps in efficiency arise as they intentionally slow their path to let the AGV pass in front of them. Insufficient trust, or under trust, can result in underutilization of autonomous systems.

Conversely, workers with a higher risk tolerance will speed up to try and get in front of or beat the AGV path. Excessive trust, or over trust, can lead to misuse or over-reliance on autonomy, potentially compromising safety during interactions.

Liu and his team hope to bridge the gap in research supporting development of an adaptive framework accounting for human trust in the context of human-AGV interaction within the manufacturing environment.

By formulating computational models to predict workers’ trust in large manufacturing sites, researchers hope to develop an adaptive human-in-the-loop framework to dynamically control and plan the paths of AGVs.

Successfully calibrating AGV technology in alignment with human trust, will help AGVs be seen as cooperative partners that aid human workers rather than intrusive elements

“My hope is to make AGV integration into manufacturing plants a smoother process,” says Liu.