Alina Kirillova 3D printing hydrogels for biomedical printing applications

Author: Zach Clemens

Author: Zach Clemens

Alina Kirillova, assistant professor of materials science and engineering, and her team at the Active Polymer Materials Lab focus on polymer-based materials for various biomedical applications, emphasizing the material’s structure and resulting chemical and mechanical behavior.

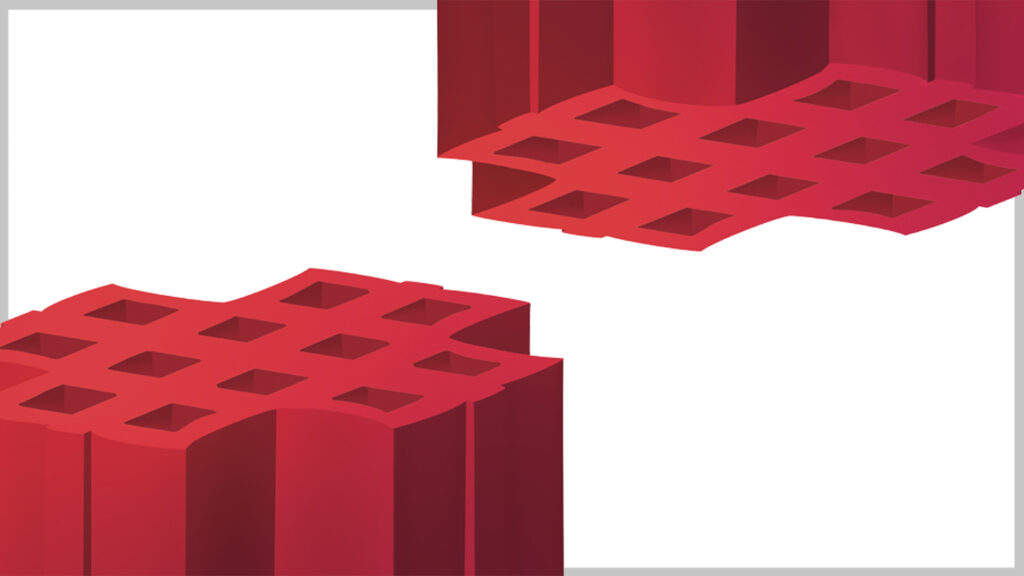

“We have made significant progress in 3D printing hydrogels into porous 3D structures, which is a challenging task due to the softness of these materials. Vat photopolymerization of biocompatible hydrogel systems has proven to be an efficient strategy to achieve well-defined porous architectures,” Kirillova said.

These structures are currently undergoing testing for their biological properties in cell and animal studies by collaborators at Iowa State.

“In terms of rigid polymer resins, we conducted a systematic study involving different resin materials and printing methods to investigate how the parameters of the porous lattice structure and the material itself influence the mechanical behavior of printed scaffolds. We found that within the same material, the structure significantly affects the compressive properties of the scaffolds,” She said. “For instance, triply periodic minimal surfaces, such as the gyroid architecture, perform better than strut-based architectures at the same porosity levels. This insight guides us in selecting structures to test with the biodegradable rigid polymers we are synthesizing.”