New REMADE project: Eco-friendly strategies to remove metal corrosion

Author: Cyclone Engineering

Author: Cyclone Engineering

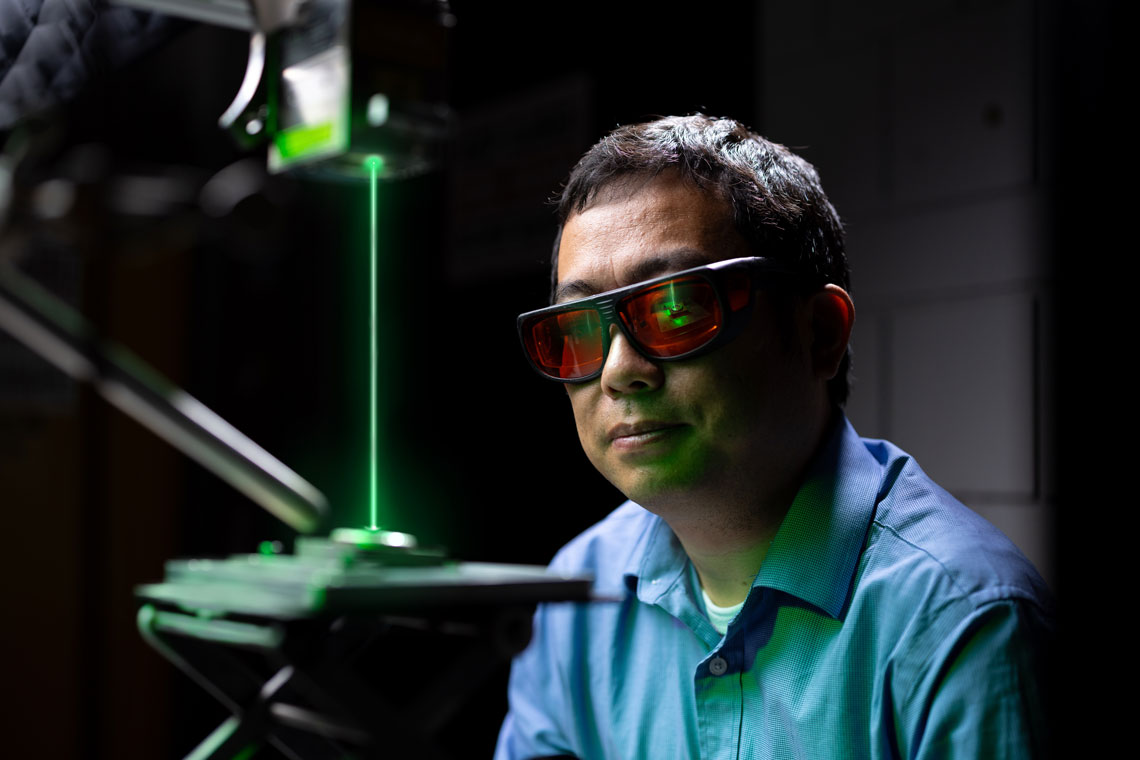

Yiliang (Leon) Liao, associate professor of industrial and manufacturing systems engineering, leads a new project to develop hybrid laser surface processing technology that will be an easy-to-use, highly controllable and eco-friendly solution for metallic surface remanufacturing.

The work is supported by $880,000 in funding from the Clean Energy Manufacturing Innovation Institute for Reducing Embodied Energy and Decreasing Emissions (REMADE).

Liao will be joined on the team by Beiwen Li, assistant professor of mechanical engineering, along with collaborators from the University of Nevada, Reno and the University of Dayton. The research team will collaborate with Volvo to investigate end-of-life reuse of metallic components.

Hybrid laser processing technology addresses the current limitations of the conventional “burning + blasting” process, which has technical barriers and high energy consumption and cost. The team’s discoveries could have a significant impact on the automotive and aerospace industries, military, and energy infrastructures, where remanufacturing and repair of metallic surfaces – particularly components with complex geometry – has widespread applications.