Peter Collins and Richard LeSar to lead multi-university team for ONR-funded metallic gradient materials project

Author: Zach Clemens

Author: Zach Clemens

The Office of Naval Research has funded a new project to conduct critical fundamental research on gradient metallic materials. The project, “Design and Manufacture of Metallic Gradient Materials,” is a three-university, five-year research partnership led by Iowa State University with critical partners from Pennsylvania State University and the University of North Texas. The team includes physical and mechanical metallurgy experts, materials characterization and modeling, and materials processing.

This team, which includes materials science and engineering Al and Julie Renken professor and Stanley Chair of Interdisciplinary Engineering Peter Collins, along with professor Richard LeSar, seeks to develop some of the first foundational design tools and philosophies to enable designers to consider introducing graded metallic materials as monolithic parts within their designs of advanced engineering systems.

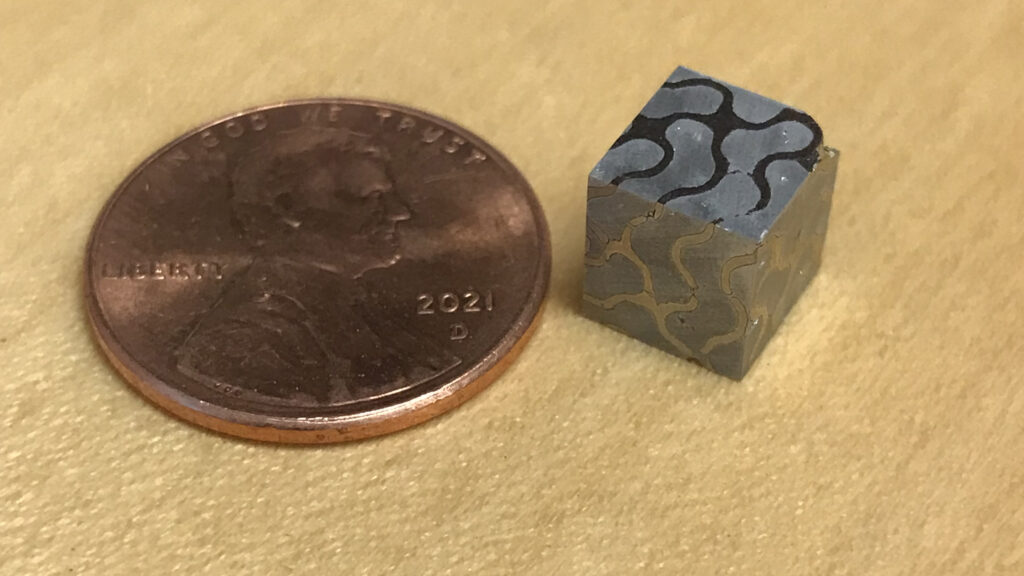

Today, advanced manufacturing processes, including additive manufacturing, make it possible to control the properties of a material locally, with sub-millimeter x-y-z precision, by controlling the materials state, including composition, microstructure, topology and more. This ability will make possible certain technical breakthroughs.

The two most notable breakthroughs will be a significant weight reduction by creating functionally graded unitized structures and the possibility of structural-functional hybrid materials representing a new class of materials. Regarding weight reduction, a unitized part with location-specific properties will make it possible to either reduce location-specific “over-design” or reduce the joining of multiple parts through mechanical means or welding. Regarding structural-functional hybrid materials, it is possible to imagine applications where one aspect of a material serves a structural purpose. In contrast, another co-continuous material enables a particular functionality, such as electrical or thermal conductivity.

Despite the exciting possibilities such materials might enable, the necessary tools to help their routine design, manufacturing, and use still need to be improved. This program will conduct fundamental research to establish new theories and strategies for designing specific gradient configurations and the precise manufacture of these designed—and embedded—gradients. This project will also develop the necessary experimental and computational tools to assess the manufactured part’s quality, properties and performance across length scales. Equally importantly, the team will develop a platform where student participants will form a critical cohort of scientists, who consider the possibilities of gradient materials for application in advanced engineering systems.