Engineering history: Iowa State collaboration caps off historic farm State Fair exhibit

Author: Anna Keplinger

Author: Anna Keplinger

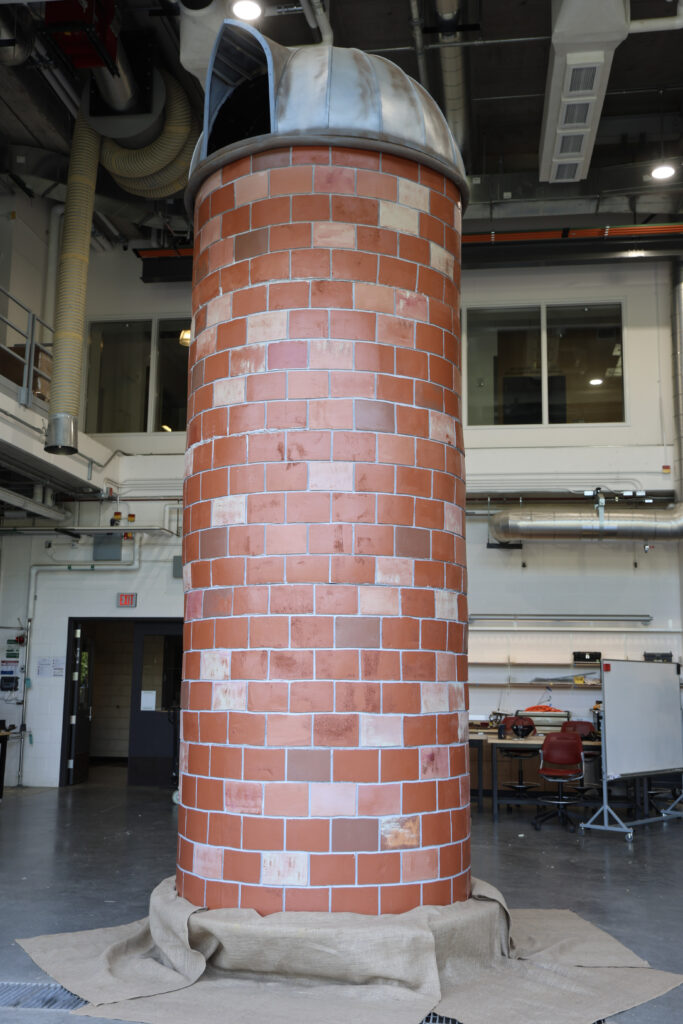

The Iowa State project team posing in front of the finished silo in their high-bay lab space. From left: Hoa Chi, Anthony Nguyen, Steve Bell, John Sheriff.

When Iowa State University alumni Roy Reiman (B.S. Agricultural Journalism, 1957) and Dwight Hughes (B.S. Horticulture, 1970) reconnected as board members of the Iowa Barn Foundation, they envisioned a tribute to Iowa’s legacy of barn building and rural craftsmanship. Their idea: a pre-fabricated model barn, built from reclaimed Iowa barn wood, to anchor a historical exhibit at the Iowa State Fair.

Piece by piece, a collection took shape, and millions have experienced historical replicas in the center of the fair’s Agricultural Building. The journey began in 2023 with the raising of the replica barn. By 2024, a restored 25-foot Aermotor windmill joined the display, complete with a rafter-mounted fan to spin its blades. As 2025 fair planning began, the team set their sights on completing the exhibit with two historical silos—one wooden, one glazed tile.

While Barn Foundation members constructed the wooden silo using reused barn boards and rusted galvanized metal, Hughes began imagining the second silo: modular, lightweight, and visually authentic.

“I was brainstorming materials—plastic, concrete, wood. I even joked about Lego bricks,” Hughes said. “Then my partner Kelly asked, ‘Why not ask Iowa State what they would do?’ So, I emailed President Wendy Wintersteen right then.”

That email sparked a unique collaboration with Iowa State’s Department of Agricultural and Biosystems Engineering (ABE).

“Our department loves a challenge like this,” Amy Kaleita, Larry and Bunita Buss Department Chair in Agricultural and Biosystems Engineering, said. “With all the moving parts, alumni involvement, and student learning opportunities, I knew we’d be up for it.”

Hoa Chi and John Sheriff, teaching lab coordinators in ABE, are no strangers to unconventional projects. They’ve supported student teams in building everything from capstone projects each semester to a 1:5 scale replica of the campanile and a 27-bell carillon, now housed in the Sukup Atrium.

“We accepted this project because it gives our students the opportunity to challenge their innovative abilities and sharpen their engineering skills,” Chi said. “Utilizing the Student Concept Lab, we get to provide support and resources for our students. We are innovative at heart, and that ties us together in this great little eco-niche called ABE at Iowa State.”

The project officially launched in teaching professor Steve Bell’s course, TSM 4150: Applied Project Management in Technology. Student teams were tasked with designing a silo that was lightweight, portable, cost-effective, and appearing historically accurate to 1910.

“It’s always a joy to see different interpretations of the same prompt,” Bell said. “It showcases our students’ creativity while grounding them in real-world execution.”

The final design combined ideas from multiple student proposals: build a mold, coat it with an epoxy release agent, fill it with insulation spray foam, and stack the pieces to form the silo. The team constructed curves, circles, and frames to prepare for spray foam application. Using insulation spray foam for structure and sculpture isn’t the typical inquiry from contractors, but Seth Shelman of SFS Sprayfoam embraced the unconventional ask.

On the first spray day, the team created a cylindrical section with precise brick outlines along the inside of the structure. When it came time to separate the foam from the mold, the form cracked, stuck in the brick crevices. Working with this foam for the first time, the exothermic reaction and complexity of the material brought the team back to the drawing board.

The team regrouped, redesigned the mold without texture, doubled the amount of release agent, and succeeded on the second attempt.

Next came the bricks. Automated methods using heated metal tracks and paint rigs failed to produce consistent results. Anthony Nguyen, a senior in industrial technology who served as project coordinator, describes the unexpected artistry the team embraced to complete the project in time:

“Our deadline was approaching, and we were at a loss for how to reach our finish line,” Nguyen said. “After a long talk as a team, we realized perfection wasn’t the goal—authenticity was. And we leaned into getting our hands dirty.”

They spray-painted each section rust red, adding texture, highlights, and shadows to each brick and a shiny silver dome by hand.

For Nguyen, the experience was transformative. “I didn’t know I’d enjoy the rush of coordination and management,” he said. “This project with Hoa showed me what I’m capable of.”

Reiman, an avid lifelong supporter of Iowa State, passed away in September 2024, just as the silo project began. The funds for the Iowa State silo were raised in memory of Reiman by friends and colleagues.

The finished silo stands 20 feet tall—a striking homage to early 20th-century farm architecture.

“The results are beyond my expectations,” Hughes said. ”It is exactly what Roy and I envisioned.”

Visit the Agricultural Building at the 2025 Iowa State Fair to see the full exhibit: the model barn, Aermotor windmill, and two silos. Grab an egg on a stick and explore Iowa’s agricultural heritage with the Iowa Barn Foundation.

Starting July 1 through August 16, the structures will be available for auction online to support the Foundation’s mission: preserving Iowa’s barns and educating the public about their historical significance.