Combating Corrosion with 3D-Printed Biofilm

Author: Anna Keplinger

Author: Anna Keplinger

The Challenge

Transportation infrastructure like roads and bridges are negatively affected by microorganisms and biofilms, as they break down materials like cement and metals, accelerating corrosion and requiring more time and money to maintain.

It is an industry-standard practice to rid structures of these microorganisms with chemicals to slow corrosion progression, often coming with high costs and risks to human and environmental health. However, what Associate Professor Kaoru Ikuma and her researchers found is that other microorganisms, or even the same ones, could actually inhibit corrosion.

Interdisciplinary Team to Create Implementable Solutions

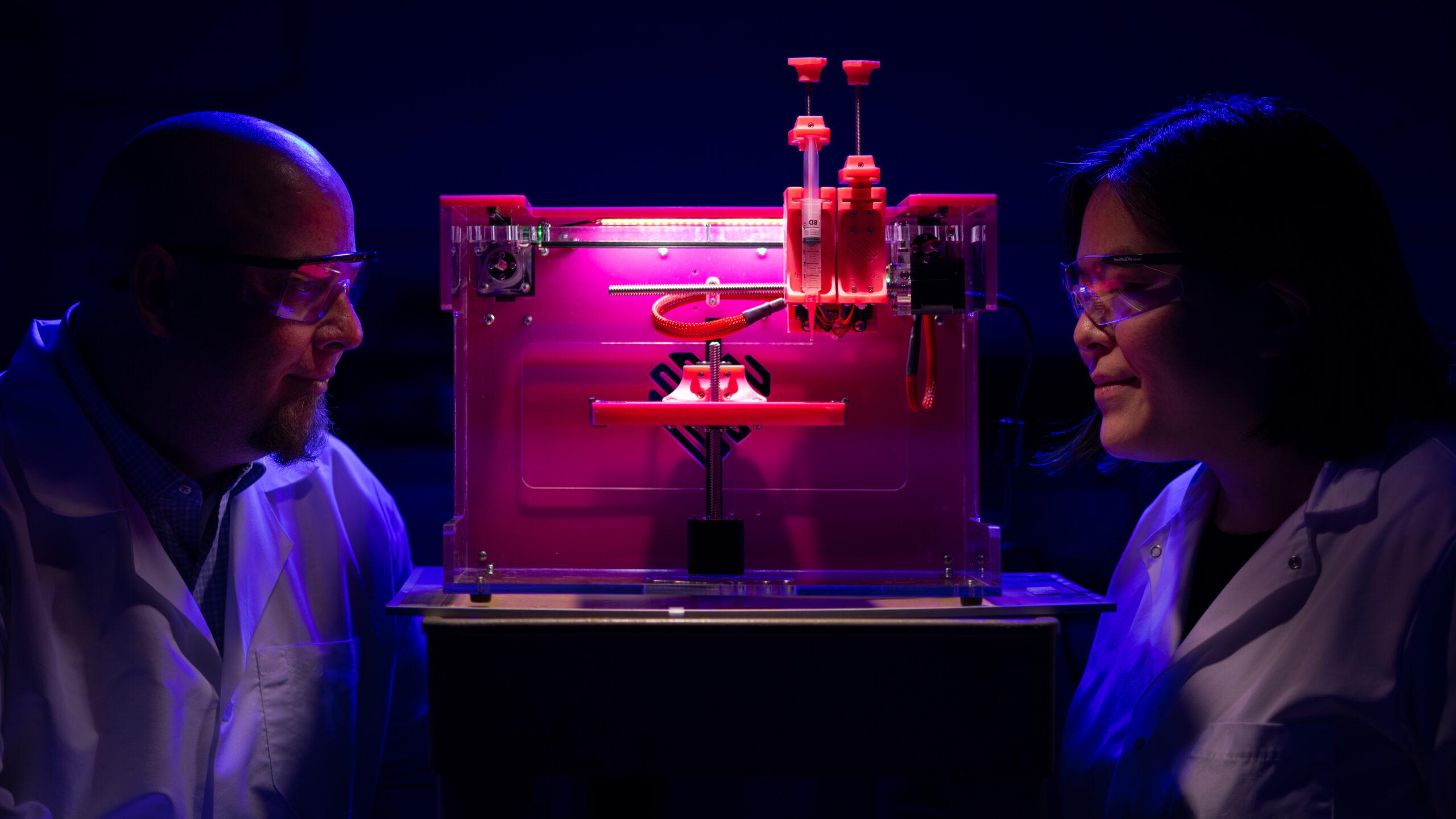

Ikuma has recruited a team to attack this problem from different angles. Ikuma focuses on the biology and biochemistry; Simon Laflamme, Waldo W. Wegner Professor in Civil Engineering, works with the machines and coding required to automate and print the substances; Roy Sturgill, assistant professor in construction engineering, rounds out the team using experience to inform real-world applications and decisions.

Experts at the University of Rochester, the Rochester Institute of Technology, and the University of Florida, who have been working with biofilm printing for years, join the Iowa State team. The innovation and practice of this team pack a heavy punch against this challenge.

“The team itself is cross-disciplinary, solving a massively complex problem that is a worldwide issue. We all have different backgrounds playing different roles,” Sturgill added.

Potential Widespread Impact

3D bioprinting is not a new technology, but using it to prevent corrosion is.

“Corrosion is a multi-trillion-dollar problem with steel and concrete, so providing a solution with a biological process could have an important financial impact and also extend the lifespan of structures. Any level of progress could be an important game-changer,” said Laflamme.

Their biofilm solution may also lend a hand to communities in need.

“If you can come up with a sustainable and self-healing system for corrosion control, it can help inequity problems because it can become more accessible to disadvantaged communities. A biological process that maintains the safety of the structures in those communities is what I’m hoping to do,” said Ikuma.

This project is funded by the U.S. National Science Foundation’s Convergence Accelerator Program, as part of Track M: Bio-Inspired Design Innovations. The program supports multidisciplinary teams of researcherssolving challenges by accelerating solutions for societal impact. Learn more about the project’s award abstract; more to come as this project continues. Check out the Environmental Biofilm Microbiology Lab webpage to see the other cool things they’re doing.