Carolyn Riedel brings energy, insight to AerE undergrad labs

Author: John Burnett-Larkins

Author: John Burnett-Larkins

The department alumna (B.S. 2015) primarily works with the AER E 160 course, titled “Aerospace Engineering Problems with Computer Applications Laboratory.” It’s a survey course with basic programming that gives students an idea of what aerospace engineering is. “We cover aerodynamics, propulsion, aircraft performance, structures, orbital mechanics, and a bit of stability and controls and systems engineering,” she explains. “We work with derived equations so students can get a sense of what elements affect the aircraft’s properties.” The course culminates in a two-dimensional rocket simulation program, designed by the department’s Dr. Stephen Holland.

Programming for the course is in the Python 3 platform, which helps users develop software, task automation, data analysis, and data visualization. “This course has changed a lot from when some of our alumni would have taken it years ago, when it was based on FORTRAN, the language program developed more than 50 years ago,” Riedel says.

One of the largest components of the AER E 160 course each semester is the Lighter Than Air (LTA) project, which sees students working in groups of five to seven people to design a craft of balsa wood and wood glue that is lighter than air that can fly through an obstacle course. Crafts are attached to a balloon that provides up to 85% of their lift. The design process involves formal presentations along the way as well as the very popular flight competition at the end of the semester, which sees the crafts and teams put to the test to see which one can best navigate the obstacle course in the Howe Hall atrium.

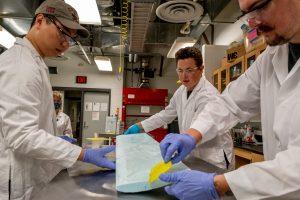

But Riedel’s student involvement does not stop there. She also oversees the lab portion of AER E 423, Composite Flight Structures, under the direction of T.A. Wilson Professor of Aerospace Engineering Ashraf Bastawros.

She describes that course as a way “to help students get more confident in testing materials.” She explains that students work with fiberglass fabric and carbon fiber prepreg (reinforcing fabric pre-impregnated with a resin system, which is donated to the department by Boeing) to help highlight composites and their properties. The class finishes with an open-ended final project that allows students to explore areas they’re interested in. Riedel says, “My favorites have included the design and manufacturing of a longboard, a carbon fiber xylophone, and the electric conductivity of a composite panel by adjusting how much carbon filler is added to the epoxy as well as the volume fraction of the matrix.

“With both classes I absolutely love to see the students’ creativity with their problem solving. And I think building something makes the hard work they put into something more tangible. Our students are really creative, innovative, and tenacious and have to work incredibly hard to survive and thrive in our program.”

Away from the labs, Riedel wrapped up her spring semester by displaying musical talent to the Iowa State campus when she made her debut on the carillon in ISU’s Campanile during a lunchtime performance. She’s been working on developing her skill with Tin-Shi Tam, a faculty member in the university’s Department of Music and Theater and University Carillonneur. Riedel says she hopes to expand her involvement in this new interest as well.