Iowa State knowhow helped launch COVID vaccine mixing technology

Author: John Burnett-Larkins

Author: John Burnett-Larkins

An email with a link to a CNN news story was recently received by Department of Chemical and Biological Engineering faculty member Rodney Fox.

“Did you see this?” said an email from Daniele Marchisio, a former postdoctoral researcher under Fox, and is now on the faculty in the Department of Applied Science and Technology at Politecnico di Torino, in Italy.

The story involved a visit to a Pfizer pharmaceutical plant in Michigan and work to manufacture that company’s COVID-19 vaccine. In the report a small device called an impinging jet mixer was discussed and hailed as key to quick and efficient production of the Pfizer vaccine.

Research by Fox, Anson Marston Distinguished Professor and Hershel B. Whitney Professor, Global Initiatives, and others at Iowa State University that began more than ten years ago created technology to assist in the development of the device.

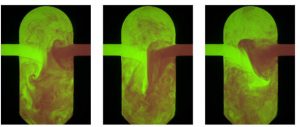

In the early 2000s work on confined impinging jet mixers was progressing and one use under study was using them to create vaccines composed of nanoparticles. Compounds are injected through small tubes at high velocities into a small mixing cavity to properly combine them.

One of the people involved in this research was Princeton University professor Robert Prud’homme. The process he used involved mixing solvents with anti-solvents in a Multi-Inlet Vortex Mixer (MIVM) in a process he calls FlashNano Precipitation (FNP). It creates particles of a tunable size that have great potential in various commercial processes. But physical handling of volatile chemicals in labs was needed to conduct the research. The danger and inconvenience posed to researchers was a serious matter.

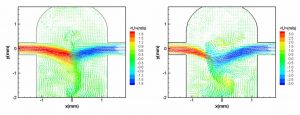

At Iowa State a research group led by Fox had been developing computer programs where computational fluid dynamics (CFD) equations could be used to predict the mixing uniformity in these types of mixing devices. This avoided having to physically handle the risky chemicals to run tests and improved the efficiency of process development.

“Prud’homme asked us if our CFD models could be used with his FNP,” says Fox. They could. Work involved Fox and Department of Mechanical Engineering professor Michael Olsen, with contributions from CBE faculty members James Hill and Dennis Vigil, ISU graduate students and international collaboration with Marchisio’s group in Torino.

“We did not actually manufacture the nanoparticles,” says Fox. “We measured mixing and supplied him with validated CFD models for nanoparticle production in the MIVM. He took that technology and applied it to the vaccine-making process.”

Iowa State researchers employed microscopic particle image velocimetry (microPIV) measurements – the first velocity measurements to be made inside a microscale reactor. They performed a statistical analysis of the velocity and used the results to develop and validate CFD models for the turbulent flow inside of the reactor.

“Those of us involved in the work here years ago were quite pleasantly surprised to learn this technology was being used to create the COVID vaccines,” says Fox. Though the ISU work is not patented, Fox says it is very rewarding that the knowhow in early work on making the process safer and more efficient came from Iowa State.