Iowa State University (ISU) Department of Civil, Construction and Environmental Engineering (CCEE) associate professor and structural engineer Simon Laflamme has been published in the prestigious 7.7 impact factor-rated ACS Sensors Journal for the creation of a sensor that helps determine the safest medical suture pattern in human and veterinary medicine.

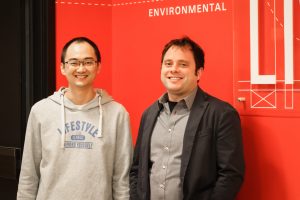

Initiated by a joint Iowa State University & University of Iowa seed grant initiative and working with the ISU Veterinary School and Mechanical Engineering, Rochester Institute of Technology (RIT), the University of St. Thomas and graduate student Han Liu, Laflamme designed this sensor to be placed on top of a suture and measure the suture’s ability to keep the wound closed based on its stitched pattern.

As outside forces pull and tug on the suture, the wound stretches apart and elongates. Medical professionals can determine the safest and strongest suture pattern by placing the sensor on different suture patterns.

“A researcher at the vet school contacted me because, at this point, he cannot measure in vivo the elongation on a dog’s skin,” Laflamme said. “I was fascinated by this concept and wanted to measure how much elongation happens in a suture. We can do this with a sensor.”

This sensor records data on the suture, measuring which suture pattern holds together a wound the best.

“The problem is that every vet has their favorite suture pattern, and no one knows which one is the best,” Laflamme said. “They also want to know what force leads to the suture breaking.”

This suture sensor designed by Laflamme is made with a flexible capacitor able to be produced in any size.

“We made a flexible capacitor, and the capacitance changes as it is stretched,” Laflamme said. “So when the capacitance changes, that means it has stretched, and that is how we measure the elongation of the suture.”

After putting the sensor on the suture, the suture will often elongate due to natural pulling, and the sensor moves with the suture – measuring the movement. A weaker suture pattern will result in the sensor stretching more to keep up with and measure the gap.

“Each type of suture pattern will be stretched differently, depending on how strong the suture is,” Laflamme said.

Right now, Laflamme and Liu are measuring this in the lab. While there are already machines that can measure suture pattern strength in the lab, there isn’t anything like this sensor that can bring those studies into the outside world.

“A machine in the lab can measure how much displacement (gap) there is, testing the strength of different patterns,” Laflamme said. “But that doesn’t account for real life. If you have a dog with a surgery that requires a suture, you can’t just put that dog in a machine. We need a sensor that we can constantly apply on animals or humans outside of the lab.”

This sensor can be used outside of the lab to measure the strength of the suture patterns on animals or in other applications.

“Eventually, we could be talking about smart band-aids,” Laflamme said. “This is the beginning of a longer-term project that we have in mind – a band-aid that gives you feedback to understand the biomechanical process of skin healing better.”

The sensor seems to have a lot of opportunities to grow – and outside of Laflamme’s usual niche, this is a project that could be the beginning of many new pathways.

“I think this is a good engineering challenge – solving a problem I don’t usually work to solve,” Laflamme said. “My specialty is flexible sensors – and therefore, I can help. I think the biomedical application is fascinating.”