A new project involving an interdisciplinary team of researchers aims to 3D print super-soft materials to create sensors that can better monitor health conditions ranging from cardiovascular diseases to COVID-19.

The $2 million project – LEAP-HI: AI-Optimized 3D Printing of Super-Soft Materials for Personalized Sensing – is supported by the National Science Foundation and led by Baskar Ganapathysubramanian, Joseph C. and Elizabeth A. Anderlik Professor in Engineering at Iowa State University.

“With afflictions such as cardiovascular disease and COVID-19, just to name a couple, health professionals need to continuously monitor local tissue damage, for example, of the lungs, heart or skin,” said Ganapathysubramanian, who also serves as a professor of mechanical engineering (ME). “Considering this demand cannot be met using current sensing technology, our interdisciplinary research team is exploring 3D printing super-soft materials that would allow us to manufacture sensors that match tissue material properties.”

The research team will oversee the development of super-soft materials, manufacturing processes and device physics to develop low-cost, personalized sensors that can be fabricated on demand.

“We propose to overcome the limitations of conventional sensor technology by developing fundamental techniques for 3D printing personalized sensors using emerging materials that are biocompatible, soft and tailored to meet the demands of health monitoring,” the researchers wrote in their grant proposal.

Their objective involves co-designing polymer chemistry, 3D printing strategies and material performance using a unique combination of synthesis, characterization and multi-physics simulations. The researchers will also integrate artificial intelligence, specifically machine learning.

The research team includes data scientists, manufacturing experts, chemists and materials scientists, along with medical advisors. Ganapathysubramanian is the project’s Principal Investigator (PI), and co-PIs include Michael Chabinyc, chair of and professor in the materials department at the University of California, Santa Barbara (UCSB); Soumik Sarkar, Walter W. Wilson Faculty Fellow in Engineering and associate professor of ME at Iowa State; Adarsh Krishnamurthy, associate professor of ME at Iowa State; and Christopher Bates, assistant professor of materials at UCSB.

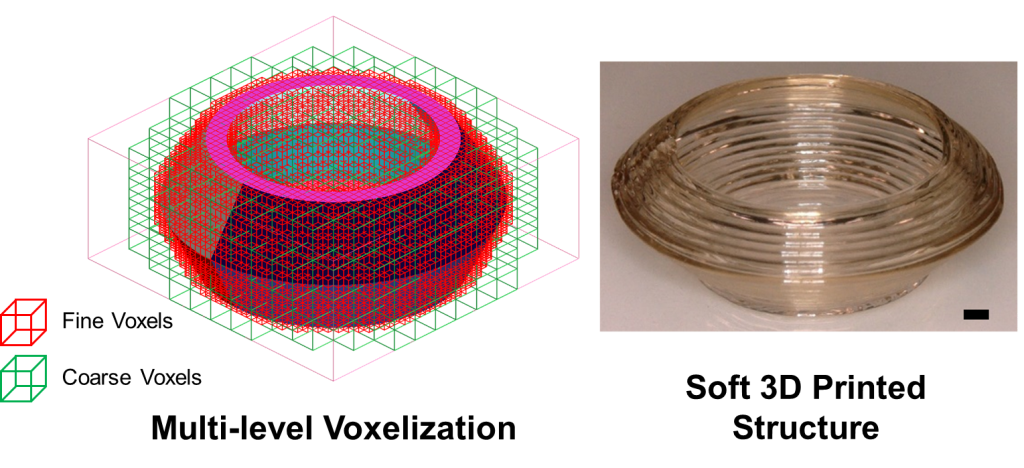

The researchers will use a convergent research approach that leverages multi-level, voxelized 3D-printing frameworks (Krishnamurthy) that incorporate (physics-aware) machine learning models (Ganapathysubramanian, Sarkar) to optimize process-structure-property relationships (Ganapathysubramanian and Krishnamurthy) in the development of super-soft, 3D-printable elastomers (Bates and Chabinyc).

The project will be integrated into the coursework associated with the newly established undergraduate minor in cyber-physical systems (CPS). The State of Iowa recognized the need for CPS and approached Iowa State University to develop educational content in manufacturing 4.0 and cybersecurity.

“With this motivation and the demand from industry stakeholders of Iowa State University’s College of Engineering, the CPS minor focuses on sensing, advanced information processing – such as data analytics and machine learning – and control of manufacturing systems,” said Krishnamurthy.

Work on this project started in August 2021, and funding will continue through July 2026.