Martin Thuo studies low-cost nanoparticle production

Creating multi-layer, squishy or solid, nanoparticles is difficult and often requires sophisticated, expensive equipment. But that didn’t stop materials science assistant professor Martin Thuo, who, with his team, run a lab where frugal science is a central theme.

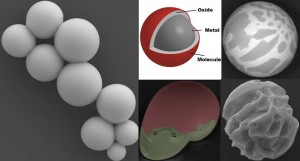

He and his postdoc, Dr. Ian Tevis, set out to develop a low-cost approach to nanoparticles synthesis. More specifically, they wanted to find a low-cost “scissor” to chop blocks of metals into small particles while also forming and organizing other layers on the metal surface to create an onion-like, micro- or nanoassembly.

A nanoparticle is the division of a micrometer 1,000 times and is roughly equivalent to 1/1000 the thickness of a hair strand. Thuo says nanotechnology is powerful because it offers unique properties; for example, nanoparticles from the same metal have different colors depending on their size.

He and his team found two “scissors” to achieve their research objectives. They first used a kitchen blender to breakdown liquid metals into particles at all size scales from nanoparticles to micro-particles. The resulting squishy liquid metal nanoparticles have three layers, composed of three different types of materials. Thuo and his students hope that by replacing the top layer of the particle with biologically important molecules, they can use these particles to deliver drugs or genetic materials. These particles being soft and squishy, they hope, will flow and penetrate hard tissue better than traditional hard metal nanopartilces.

“The advantage in this case is that when the drug is attached to the squishy particle it can respond to acidity changes in the body. The drug would only be released in regions with high pH, a common feature of tumors and inflammation; thereby, attacking the disease or foreign object only where needed,” Thuo said. “One of the biggest challenges in pharmaceutics is stability and targeted delivery. But with these kind of systems, we hope to develop a general, affordable option.”

The second “scissor” Thuo discovered was a modified low-cost dremel tool. Using the tool in conjunction with the blender, he was able to separate different metals from an alloy so the nanoparticle contained two ordered metals layers on their surface leading to solidification. He experimented with different shear levels in the blender and dremel, and as a result, different metals came to the surface and created unique patterns. He and his team are using these new solid particles to perform multiple reactions at the same time.

“By introducing multiple metals on the surface of a single solid particle, not only do we get two catalytic surfaces, but due to the size, we increase the overall surface available for chemical transformations,” he explained. Thuo and his team think this approach could be applied in biomass conversion, waste gas treatment, and affordable catalytic surface development.

Also notable, this approach continues Thuo’s low-cost, and sustainable, research goal in two ways – the metals are relatively inexpensive and the catalysts can be regenerated many times by reconstituting the alloys and blending them again.

Outside of the major implications of his work, Thuo wants to teach people that science is fun. After the top layer of a nanoparticle is removed, he can combine and manipulate different metals to create nanoparticle forms into objects, such as a tiny seahorse, a hat or a turtle.

“The ability to make art out of these particles is not just for fun. It demonstrates the power of coupled platforms, that is, affordable particle synthesis, self-assembly, and milling at the nanoscales. With this approach, we can achieve nanosculpturing to create irregular or complex shapes out of these systems,” Thuo said.

His research was recently published in Langmuir, a journal published by the American Chemical Society. Thuo was also recently honored by the College of Engineering as a Black & Veatch Building, world of difference faculty fellow.

I. D. Tevis, L.B. Newcomb, M. M. Thuo, Langmuir.2014 30, 14308–14313