Two scientists at the U. S. Department of Energy’s Ames Laboratory have developed a computational method that will make the search for new catalysts more precise and less painstaking. In turn, the discovery could speed the development of efficient hydrogen storage materials, one of the technological obstacles for getting greener, cleaner hydrogen fuel cell vehicles on the road.

Nano Letters, “A Comprehensive Search for Stable Pt-Pd Nanoalloy Configurations and Their Use as Tunable Catalysts,” Ames Laboratory chief research officer Duane Johnson and associate scientist Linlin Wang, together with Teck L. Tan and Kewu Bai of the Institute of High Performance Computing, Agency for Science, Technology, and Research in Singapore, outline a unique and accurate computational method for finding the most stable alloyed nanoparticles that give the desired hydrogen adsorption.

Nano Letters, “A Comprehensive Search for Stable Pt-Pd Nanoalloy Configurations and Their Use as Tunable Catalysts,” Ames Laboratory chief research officer Duane Johnson and associate scientist Linlin Wang, together with Teck L. Tan and Kewu Bai of the Institute of High Performance Computing, Agency for Science, Technology, and Research in Singapore, outline a unique and accurate computational method for finding the most stable alloyed nanoparticles that give the desired hydrogen adsorption.

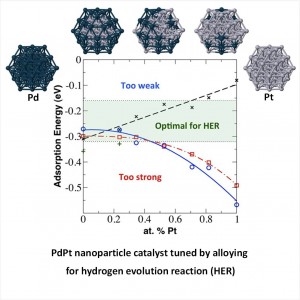

Finding a catalyst, like the popular palladium and platinum alloys used in this study, that both adsorbs hydrogen readily and then desorbs it at a controllable rate and temperature is the key materials design challenge of hydrogen fuel cell technology, explained Johnson.

Part of the problem, he said, is designing at the nanoscale.

“You can’t just sit there and watch the catalytic reaction on the nanoscale,” said Johnson. “You can make nanoparticles and monitor flow reactions and say it worked or it didn’t work. Then you do a year of experiments on what the nanoparticles look like and you try to infer what’s going on but you can’t really look at it. It’s a hard, lengthy process. But, we can look at all the possibilities in the computer quickly.”

Additionally, previous computational methods were incomplete and limited the number of possible configurations to those nanoparticles with very high symmetry so that algorithms would process quickly.

Integrating their own ideas and those of others worldwide, The Ames Lab and Singapore team developed a novel software package that uses the data from reliable but computationally costly quantum mechanical calculations. The data are automatically mapped to a simpler classical model so that any particle configuration, composition or shape can be explored versus temperature, but without restrictions on symmetry of the particle or the need for more quantum-based data. The tool then can evaluate millions of possible arrangements of atoms in the particles, the hydrogen evolution reaction in each and compare them very quickly.

“This method searches all possible alloy configurations, with and without adsorbed hydrogen, to determine the optimal nanoparticle composition range for desired hydrogen adsorption energy,” said Wang. “If we do this computational “design” before we do the actual experiment, we know exactly what properties we will get. We are really attempting to design the catalyst from the very beginning.”

The broader and more complete search capability discovered important possibilities.

“We found that these configurations that are asymmetric turn out to be really important,” said Johnson. “Nobody realized these asymmetric configurations are really the most general ones and control adsorption. And surprisingly, some intuitive expectations for the alloying behavior with hydrogen adsorption were wrong – which highlights the importance of such predictive tools.”

Wang said that the method and tool can also be applied to nanoparticles with more than two components, allowing control of reactivity at lower cost or designing in multiple properties. It also can search for other desired properties, such as magnetism.

See the complete paper in Nano Letters at: http://pubs.acs.org/doi/abs/10.1021/nl302405k